The Economic Role of Packaging

There are approximately 7 billion human beings on the planet and unless one is completely remote from modern civilization, one is constantly touched by packaging in some way or the other. Some people may not be aware of the economic value of packaging, simply because they are not in the packaging conversion industry, nor in the packaging supply chain, nor in the retail industry, and so they do not appreciate the role packaging plays in getting product to them. But without packaging, the Gross Domestic Product (GDP) of a country would significantly reduce in value. This is simply because product cannot be shipped from source to manufacturer to retailer to consumer, through the supply chain, without proper packaging. Packaging must be developed from specific materials, into specific shapes and texture, scientifically designed to suit the product being packaged, to suit the hazards of the transit journey, to maximise the shelf life of the product and to ultimately positively influence the consumer purchase decision, resulting in a contribution to the GDP of the country.

Therefore it is quite understandable to accept the total packaging sales in a country as an indicator of the strength of the country’s economy, as almost everything sold must first be packaged. Yet the total value of a country’s packaging as a percentage of the country’s GDP is small.

As an example in 2012, the total value of South Africa’s packaging industry was around R43-billion, contributing about 1.5% to South Africa’s GDP. Although the R43-billion packaging GDP was just 1.5% of SA total GDP of R2.86 trillion, almost all of the consumer / industrial goods GDP and much of the service industry GDP relied heavily on packaging for realization.

In achieving the sale of the product, the packaging must also protect the product, not only from transit and physical damage, but also from microbial and bacterial deterioration as well as climatic hazards, like heat, cold, moisture, frost etc. In this role, especially with respect to food product, packaging significantly reduces the wastage of food during the transit journey. Packaging must also identify, track and trace the product. Consumers are now more than ever aware of product shelf lives, product traceability to the packer / product originator, enabling effective product recall in instances where product integrity is questionable. Packaging must also differentiate itself on the shelf where it competes with thousands of other packaging for consumer choice. Also, the packaging must inform the consumer. The consumer purchase decision is made between 2 – 5 seconds once the package in the hands of the consumer in the shopping aisle. Therefore it is imperative that the packaging talks intelligently to the consumer within this crucially miniscule time interval. The package also plays a role in effective merchandising of the product on the shelf because it must conform to the height, width and footprint as per shelf requirements. Unitization of product into a point of sale SKU is yet another role of packaging, as packaging serves to group or consolidate product into ‘a packet of cigarettes’ or a ‘box of Easter eggs’ etc. In so doing the package also facilitates the solution of logistical difficulties, enabling effective transportation of the product.

An important part of packaging’s role is to ensure that the energy invested in producing goods and transporting them from source through the supply chain to the shops and home is not wasted.

Therefore packaging must be viewed as a benefit to be maximized rather than as a cost to be minimized, so that products, through their packaging, are made available at the points of sale, and sold to enhance GDP, in support of the World Packaging Organization’s motto, “Better quality of life, through better packaging, for more people”

Packaging and Sustainability - Interesting Global Facts

Even though packaging is an extremely small fraction of a country’s GDP, and consequently, also a small fraction of the country’s waste stream, the packaging industry, globally, is nevertheless, aware of the impact of packaging on the future of the planet.

From 200 BC to the year 1850, human population grew modestly to about 1 billion people. After the onset of the Industrial Revolution, the discovery of oil, as well as the discovery of medicine, there has been a population explosion. The global population at the start of the 21st century was 6 billion people, which was double that of 50 years before. The graph below indicates the human growth profile over the years and also projects human growth into the year 2100 as high, moderate and low growths as predicted by the UN.

Consequently, and coupled with the Industrial Revolution back in the 1800’s, the fossil fuel usage has shown a dramatic increase since 1750 and carbon dioxide emissions are now exceeding the atmosphere’s capacity to absorb carbon dioxide.

The 2007 IPCC (Intergovernmental Panel on Climatic Change) report estimates that anthropogenic greenhouse gas emissions was 49 billion tons in 1994, an average of 130 million tons each day is exhausted into the Earth’s atmosphere, all due to rapid industry expansions and man’s desire for lifestyle changes.

To this end, packaging industries across the continents, networked through the World Packaging Organization (WPO) as well as many other global packaging material specific organizations, are all working towards a common goal, to constantly reduce, rework, recycle, recover, renew packaging materials, enabling a measurable reduction on the total Global Packaging Carbon Footprint. This is achieved with new mindsets at the point of packaging design. At the design stage, choice of materials is vital, choice of pack design, choice of manufacturing process, choice of print method, choice of supply chain are all considered so that the impact of packaging on the planet is substantially minimized. But it is important to understand and accept that packaging designs supporting reduction in carbon footprints rely on past packaging design successes as well as on current development of packaging material technologies that can enable such progressive developments in packaging. Therefore we say that the future of packaging design is really the past of packaging design being modified in the present.

It is important for humanity to understand that resources are limited and that every effort must be made to conserve resources and adopt a responsible commitment to leaving a legacy to future generations.

Facts on Packaging Material Reduction – a South African Experience

- The tinplate beverage can in SA has reduced to a mass of below 30 grams today versus a mass of 62 grams in 1966. In fact the new aluminum beverage can in SA is now just 13 grams.

- The 2 litre PET bottle has reduced to a mass of less than 50 grams today versus a mass of 90 grams in 1979.

- Glass wine bottles today are 32% less than they weighed 7 years ago.

- Detergent refill packs have reduced packaging material by 70%.

- The mass of expanded polystyrene containers has seen a reduction in weight by 20%, over the past 20 years.

- The cement industry uses a standard 50 kg bag now that is 2 ply at 210 g/m2 versus the 4 ply 360 g/m2 material used in 1980’s.

These great strides in packaging design, enabling reduced packaging energy and material consumption, translates to reduced warehousing costs as well as reduced supply chain costs, reduced masses to landfill, and therefore, ultimately, a reduction in the overall packaging carbon footprint. Such paradigm shifts in modern packaging design thinking are driven by commercial and environmental pressures within SA and this trend is true for most countries, depending on extent of their economical development.

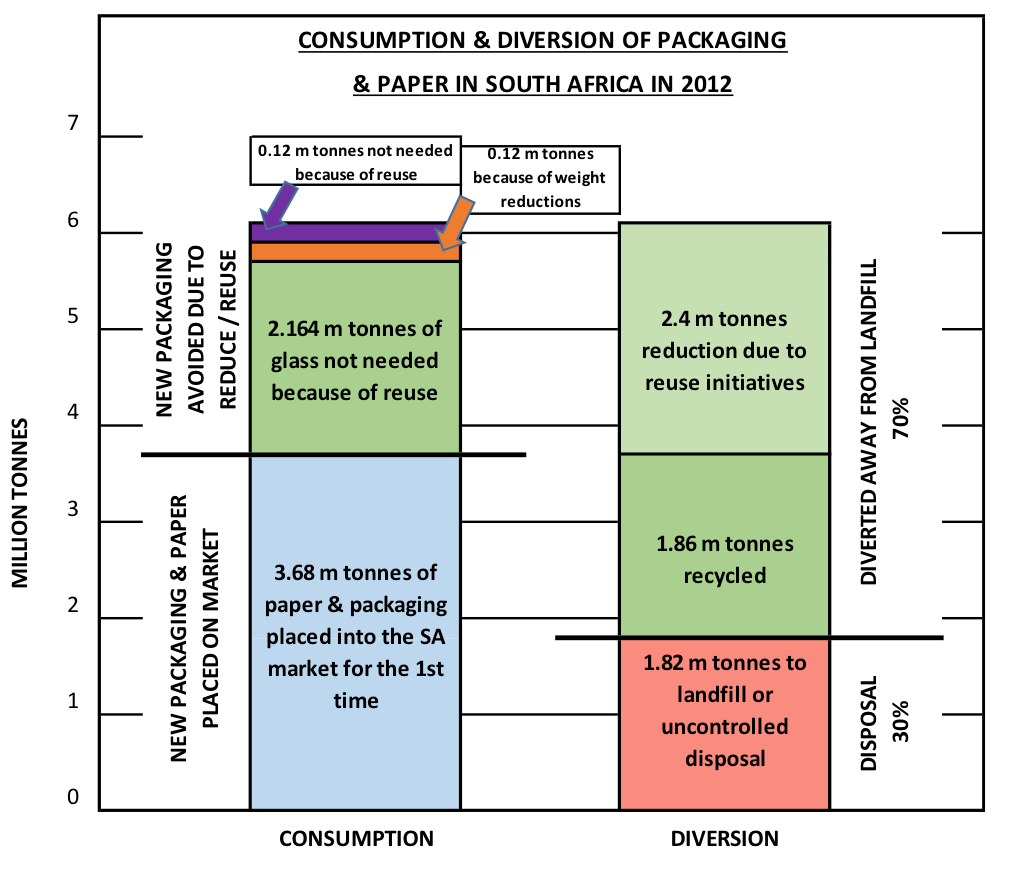

The chart below shows the SA consumption of materials in tons (2012) as well as the tons of packaging material avoided as a result of proactive packaging management in SA.

SA Packaging Statistics

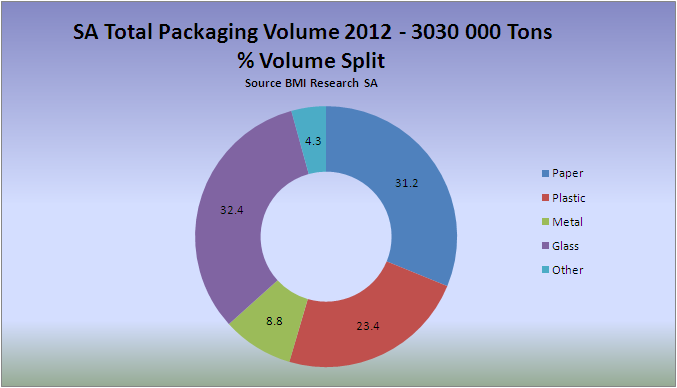

SA Packaging by Volume

South Africa’s packaging industry manufactured just over 3 million tons of packaging during 2012. Glass and paper being the largest contributors to the packaging industry of South Africa at 32.4% and 31.2% of total packaging market volume. Refer graphical representation of packaging volume data for 2012 below.

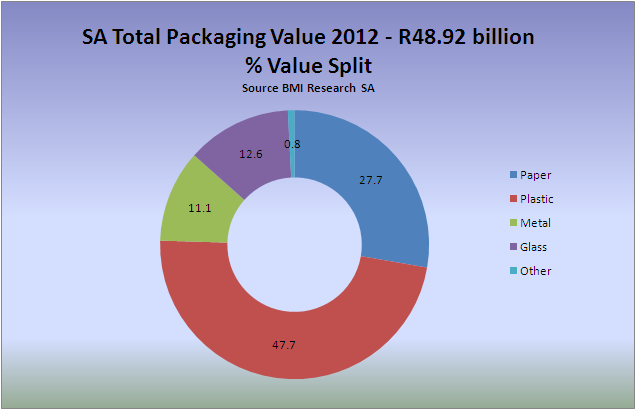

The total rand value of the packaging industry of South Africa’s for 2012 was R48.92 billion, contributing 1.5% to the GDP of South Africa. Although the glass and paper sectors manufactured the largest volume of packaging, plastic contributes the most in value with 47.7% share. Plastic remains a more popular and economical packaging type choice. Refer graphical representation of packaging value data for 2012 below.

Material growth over time

Over the years, plastics have shown a steady increase in tonnage as a preferred packaging format. This is because of the vast technological advancements made with respect to barrier properties, material strength, visibility, lamination, recyclability etc. Hence the age we live in is regarded as the “Plastics Age”. Plastics will continue to enjoy the limelight in the packaging arena as the energy consumption in plastic conversion remains amongst the lowest.

Packaging Organizational Bodies in SA

1. PACSA

The Packaging Council of SA (PACSA), http://www.pacsa.co.za/, has been the voice between the SA Packaging Industry and the government, and has therefore played a vital role in shaping the SA legislation on environmental expectations. In spite of the many benefits of packaging to modern society, it does enter the waste stream where it can be highly visible as litter. The various sectors of the packaging industry have embarked upon a number of initiatives, as a form of voluntary extended producer responsibility, which are aimed specifically at addressing the issue of packaging in the waste stream. These initiatives are elaborated on under the four broad headings of Reduce, Re-use, Recycle and Recover.

Collectively these initiatives are estimated to have diverted 65% of packaging used in SA from landfill. Refer PACSA website for greater detail on objectives / deliverables / achievements and future strategies.

2. IPSA

Unlike PACSA, which represents the packaging converter industry in SA, the Institute of Packaging SA (IPSA), http://www.ipsa.org.za/, is a body that networks some 850 packaging professionals across SA, with core objectives being, amongst others, Packaging Education, Packaging Sustainability and Packaging Networking.

Amongst IPSA’s many value offerings to the Packaging Industry is the One Year Diploma in Packaging Technology and the Advanced Packaging Programme, both designed to educate people in the art and science of packaging, and to create awareness of packaging design requirements in support of Environmental Sustainability. Also in its arsenal of offerings is Gold Pack and Student Gold Pack, both are highly recognized Packaging Award Programmes, designed to stimulate creative and innovative packaging design, by the packaging industry and by packaging students respectively, again, in support of the Environmental Sustainability theme. IPSA has also produced a packaging textbook, Handbook of Packaging Technology, currently in its 2013 edition. This text has been as a result of research and input of a number of competent SA individuals and organizations. The text is rated as amongst the best in the world in its category. IPSA’s website, see link above, showcases the inner workings and deliverables of the organization.

Nanotechnology – The Future of Packaging

“Achieving more with less”

Nanotechnology is promising new and invaluable techniques as well as paradigm shifts in thought processes for the packaging industry. The radical technology is set to revolutionize the concept of packaging design by maximizing the primary functions of packaging, while protecting the environment as well as creating economic and social benefits not only in the packaging industry but also across the spectrum of manufacturing.

Nanotechnology refers to ‘the control or active change of matter at the atomic, molecular, or macromolecular level, in which one of the components affects functional behavior.’ Nanotechnology therefore manages particles no more than 100 nanometers in any dimension. To contextualize this dimension, a human hair is about 70 000 - 80,000 nanometers thick. Nanoscience and nanotechnology involve the ability to see and to control individual atoms and molecules. All matter in the universe is made up of atoms—the foods we consume, the clothes we wear, the buildings and houses we live in, and our own bodies. These atoms are impossible to see with the naked eye. In fact, it’s impossible to see with the microscopes typically used in a high school science classes. The microscopes needed to see things at the nanoscale were invented relatively recently—about 30 years ago.

Once scientists had the right tools, such as the scanning tunneling microscope (STM) and the atomic force microscope (AFM), the age of nanotechnology was born. Today, nanoscientists are finding a wide variety of ways to deliberately make materials at the nanoscale, to take advantage of their enhanced properties such as higher strength, lighter weight, increased control of light spectrum, and greater chemical reactivity than their larger-scale counterparts.

Material development efforts focus primarily on enhancing thermal, mechanical, and barrier properties; although different industries have different hopes and goals for nanoparticle applications.

For some time now, food has been packaged in a protective, oxygen-free atmosphere. Standard packing film made from flexible plastics, however, is slightly permeable to oxygen and other gases. Over time, this means that the protective atmosphere can leak out, and oxygen can leak in, damaging the food.

A coating of metal or glass, which are totally impermeable to gases, would prevent this from happening - this is obviously impractical however, as it would reduce flexibility, and would be much more expensive than plastic packaging.

This is where nanotechnology comes to the rescue - a coating just a few nanometres thick is sufficient to create an impermeable layer, without compromising on flexibility or adding a great deal to the cost.For some time now, food has been packaged in a protective, oxygen-free atmosphere. Standard packing film made from flexible plastics, however, is slightly permeable to oxygen and other gases. Over time, this means that the protective atmosphere can leak out, and oxygen can leak in, damaging the food.

A coating of metal or glass, which are totally impermeable to gases, would prevent this from happening - this is obviously impractical however, as it would reduce flexibility, and would be much more expensive than plastic packaging.

Nanotechnology represents a wide array of potential benefits in packaging, to name a few areaFor some time now, food has been packaged in a protective, oxygen-free atmosphere. Standard packing film made from flexible plastics, however, is slightly permeable to oxygen and other gases. Over time, this means that the protective atmosphere can leak out, and oxygen can leak in, damaging the food.

A coating of metal or glass, which are totally impermeable to gases, would prevent this from happening - this is obviously impractical however, as it would reduce flexibility, and would be much more expensive than plastic packaging.

This is where nanotechnology comes to the rescue - a coating just a few nanometres thick is sufficient to create an impermeable layer, without compromising on flexibility or adding a great deal to the cost.s of application the list below refers:

1. Food packaging

Currently foods are typically packed in plastics wraps with modified atmospheres, and with reasonably good barrier properties. However with time the protective internal atmosphere can diffuse out and oxygen is able to penetrate these packs and cause the food to deteriorate due to oxidative rancidity.

Imagine a plastic coated with just a few nanometers of metal, giving the laminate the impermeability of the metal nanofilm, keeping the food fresh for longer, whilst retaining the flexibility of the film? Imagine antibacterial nanocoatings on film that significantly decrease microbial activity enabling longer shelf lives? Imagine smart nanopacks that are able to regulate internal temperatures within a pack and that can warn a consumer when the contents have exceeded a predetermined threshold temperature? Imagine “self healing” packaging which is able to repair itself, if damaged during the transit journey?

These are just some of the potential avenues for food packaging using nanotechnology.

2. Packaging material properties are enhanced by inclusion of nanoparticles, increasing

a. Mechanical strength

b. Barrier properties

c. Moisture retention

d. Improved clarity

e. Thermal insulation

3. Nano Barcodes – track & trace, movement sensing, enabling easier point of sale transactions.

4. Production process for paper with nano particle inclusions.

5. Nanoscale pigments for inks, for print identification and traceability.

6. Nanomaterials for color without use of dyes or conventional pigments.

Nanotechnology Concerns

Although nanotechnology has substantial potential in changing the way we think of packaging, the wider longer term ramifications of this technology is yet to be understood. It must be remembered that in as much as nanotechnology is “smaller and lighter”, the impact on humans, given the speed of nanoparticle travel and depth of nanoparticle organic tissue penetration, is still to be understood.

Also, we are not substantially aware of the impact of nanotechnology on packaging recycling and reusing as these nanoparticles may / could result in significant complications in such material recovery processes.

Given these uncertainties, weighing up the advantages on nanotechnology against the risks, industry is naturally extremely cautious in the approach to nanotechnology.

Disclaimer

This article has been researched and presented as an overview of the role of packaging in society, more so from an economical, environmental, and logistical impact. Whilst every care has been taken to ensure that the facts supporting this article are accurate at the time of print, the author, as well as websites / journals publishing this article, will not be responsible for the use / interpretation of this article or part thereof.

This article is copyright and may not be reproduced in part or in full without the express authority of the author.

Acknowledgement and thanks

- PACSA, http://www.pacsa.co.za/,

- BMI Research http://www.bmi.co.za/

- IPSA, http://www.ipsa.org.za/

- IPSA – Handbook of Packaging Technology 2013 edition

Kishan Singh

National Chairman

The Institute of Packaging South Africa

07 May 2014