|

President’s Word

From incremental to disruptive innovation: the packaging industry

heats up!

Luciana Pellegrino

President of WPO

Greetings!

We're back with another exciting update on the global

packaging industry. Since our last edition, there's been a flurry of activity!

Our dynamic industry is constantly evolving, and the months of April, May, and

June pushed boundaries and reshaped possibilities once again.

Innovation fueled by collaboration

Packaging innovation thrives at the intersection of technology,

sustainability, market demands, and passionate professionals. Recent months

provided opportunities for global collaboration and exploring future trends. And

WPO was all around promoting the connection of the global packaging community. I had a busy schedule as well, but not alone, luckily counting

with Board Members from all around the globe on the ground!

CiclePack Show in Chile: In April it was my honor to represent

WPO at CiclePack Show in Chile, organized by our packaging member, CENEM. The

show gathered Latin American exhibitors and visitors to explore sustainable

packaging solutions, besides some very interesting panels, and it is rewarding

to acknowledge the maturity of the show and its positive impact to foster

packaging advancement and business opportunities in the region.

Propak Mena, Egypt: Invited by Informa Markets, in May, it

was a remarkable experience to join a bold delegation of WPO Board Members from

the Arab and African regions, getting to know new members in person, and reconnecting

with long time colleagues, counting as well with WPO’s national member, the

Chamber of Printing and Packaging Industries. WPO’s training program took place

alongside the show while Board Members participated in various panels,

including a Round Table on Sustainable Food Systems organized and chaired by

LibanPack and UNIDO, supported by Informa Markets and WPO.

Last but not least, since we are all driven by packaging

innovation, it was an immense satisfaction to take part of the gala ceremony of

the Arab StarPack Awards.

Drupa Show: In the meantime, WPO Board Members attended the

Drupa show, experiencing groundbreaking innovations driven by AI. These

advancements promise to significantly enhance accuracy and efficiency in

printing and packaging processes, even offering micro-mass personalization

possibilities.

Expo Pack Mexico: June started with Expo Pack Mexico,

organized by PMMI, and it was an immense pleasure to visit the show on behalf

of WPO, and to attend a panel on Women in Packaging. We explored how companies

can support initiatives to empower women in reaching leadership positions, from

strategic career roadmaps and social culture, building to foster childcare

support infrastructure.

During this visit, I had the honor of presenting the awards

at the Envase Estelar ceremony, organized by WPO's member AMEE (Mexico's Packaging

Association). Moments like this strengthen our industries and empower their

professionals.

Propak Asia and WorldStar Award Ceremony: a global celebration

of packaging! Finally, these dynamic months culminated with Propak Asia in

Bangkok, and WPO had a bold participation throughout the event counting with 40

Board Members, from 29 countries. WPO's participation was significant at

Opening Ceremony, a Round Table with the Asian packaging bodies, innovation

stage and zone with packaging samples, conferences and panels, and we launched

the Networking Cocktail for WPO Corporate Partners.

This event had as well a special meaning for me as I chaired

my first WPO Board Meeting, as President, alongside with WPO’s Vice Presidents

and the first Executive Meeting with the new Ambassadors.

To close, an unforgettable night handling the awards at the

unique WorldStar Awards Ceremony, in a event counting with more than

300 participants from around the world and WPO Board Members celebrating

packaging innovation on a global level.

And this is just the beginning! Enjoy this insightful

edition of WPO News.

[email protected] [email protected]

WPO – World Packaging Organization

WPO – World Packaging Organization

www.linkedin.com/in/lucianapellegrino www.linkedin.com/in/lucianapellegrino

@WorldPackOrg1

@WorldPackOrg1

worldpackagingorg

worldpackagingorg

World Packaging Organization

World Packaging Organization

Message from General Secretary

Recap of the WPO Meetings at ProPak Asia

Dear members, once again it's that time of

year when we come home with warm hearts after another magnificent WPO Board

Meeting. This time, we had the opportunity to meet in the stunning city of

Bangkok in Thailand and hold our meetings and the WorldStar Awards Ceremony in

parallel with ProPak Asia.

A series of strategic meetings were held,

as for our Executive Meeting, the Education, Marketing and Sustainability &

Save Food Working Groups; the Roundtable discussion entitled "Enabling

Sustainable Industrial Development of the Food Packaging Industry to Reduce

Food Loss and Waste" and finally the grandiose WPO Board Meeting. We also

used this opportunity to welcome our corporate partners to an exclusive

networking event.

At our meetings, around 40 participants

were brought together to discuss and plan for the future. The discussions were

filled with wisdom, foresight, and a shared commitment to making positive

changes. We are incredibly grateful for the thoughtful insights and visionary

ideas that were shared during this important session.

Hosting the prestigious Worldstar Global

Packaging Awards ceremony was a privilege. It was a breathtaking celebration of

creativity, excellence, and innovation in the packaging industry. We want to

extend our heartfelt congratulations to all the winners for their outstanding

achievements. Your vision and commitment to pushing boundaries have set new

standards of brilliance in our industry.

There was also the opportunity to discover

the latest packaging innovations and trends presented at ProPak Asia. The fair

presented a wide range of innovations, from sustainable packaging solutions to

cutting-edge automation technologies, which WPO members were able to learn

about.

We had some leisure time with good old

friends where we had the opportunity to taste some good Japanese food and get

to know a little better the culture of this amazing country.

Now, as we say goodbye to this incredible

week in Bangkok, we want to remind you of the exciting opportunities that lie

ahead. We are thrilled to announce that our next meeting will take place from

November 18th to 22th in the beautiful city of Buenos Aires, Argentina. Please

keep an eye on your e-mails, you will soon receive information about our next

meeting.

Until we meet again, let's carry the spirit

of collaboration and innovation in our hearts, and let's continue to make a

positive impact on the world through packaging.

And now, enjoy some of WPO moments at ProPak

Asia!

Warmest regards,

Nathália Antoniazzi

WPO Secretariat

[email protected]

Johannes Bergmair

WPO General Secretary

[email protected]

From the Editor

What we know about the Global Plastics Agreement: past discussions

and future actions.

By Liliam Benzi*

The Global Plastics Agreement is a hot topic internationally

and it is important to be updated on the past resolutions and the upcoming

steps. In April, the fourth round of discussions took place in Canada, and the

debate evolved to address the entire lifecycle of plastics. Despite being an

agreement still immature in some aspects, the fact is that the discussions are

advancing.

To provide some context, this Agreement, formally known as

the Global Plastics Treaty, is an international initiative promoted by the

United Nations (UN) aimed at creating a legally binding treaty involving all UN

member countries to reduce the production and consumption of plastics, promote

a circular economy, and improve waste management.

Interestingly, the fourth meeting faced a significant

challenge: waste management, rather than simply condemning plastic. To

understand and openly discuss what this challenge means in practice and its

impacts, some specialists recently shared important insights about the last

meeting, in Canada, and what to expect from the next meeting scheduled for

November 25 to December 1, 2024, in Busan, Republic of Korea.

They believe that the next round of negotiations will be

crucial for finalizing the Agreement's text based on a lifecycle approach, from

production to disposal. The experts also noted that previous negotiations,

including the fourth session in Ottawa, were important steps for advancing the

text of the instrument and establishing the necessary intersessional work to

prepare for INC-5.

It is worth noting that urban solid waste disposal is a

common problem in many countries and, therefore, the Agreement's main focus

should really be on waste management, involving all stakeholders. In other

words, the Agreement is an opportunity to leverage plastic disposal,

reintegrating it into the chain as a valuable raw material.

Several countries, including Brazil, strongly supports the

existence of the Global Plastics Agreement and advocates for plastic waste to

become a raw material. For this to happen, the chain must be economically

viable, which depends on consistent demand and extended producer responsibility

(EPR).

It is also important to understand that mechanical

recycling, although crucial, has its limitations. Therefore, investment in

chemical recycling is necessary, allowing for a longer cycle of plastic

materials, transforming them into molecules that can be reused as if they were virgin

materials, even for food contact. Thus, the development of new technologies by

the chemical industry is essential.

Inclusion of waste pickers, a fundamental pillar.

Another important voice in this debate are the waste

pickers. They are seen as key players in the recovery of plastic waste and

should be adequately remunerated for their work. Everyone agrees: "The

fair inclusion of waste pickers is essential. They are part of the value chain

and should be compensated for the environmental services they provide."

Equally important is designing plastic products based on

science, aiming to ensure minimal environmental impact without losing

functionality. The transformation of design is also crucial for the Agreement

to rethink the entire plastic production chain.

The industry, in turn, plays a vital role in providing

knowledge and developing new technologies. The participation of all actors –

government, industry, civil society, waste pickers/cooperatives – is crucial

for the success of the Agreement, which has the potential to transform waste

management in the world, promoting a circular economy that minimizes resource

waste and maximizes efficiency and sustainability.

As discussed in Canada, the main points of the Agreement

are:

- Improvement of waste management, including the

collection, recycling, and proper treatment of plastics to prevent them from

becoming "lost" in various ecosystems.

- Innovation and Circular Economy, promoting practices that

involve reuse, recycling, and revaluation of plastic products, and including

the development of new technologies and more sustainable materials.

- EPR (Extended Producer Responsibility) to ensure that

producers take responsibility for the waste generated by their products

throughout their entire lifecycle.

- Engagement and Education through

incentives for public awareness and education about the impacts of waste on the

environment, as well as the sustainable practices that can be adopted by

consumers.

The time is ripe for significant advances towards a more

circular economy. It is hoped that the next round of negotiations, INC5, will

result in a treaty for plastics and waste in general. It is expected that after

the next negotiations, the Agreement should be transformed into specific

decrees and regulations that will affect the entire value chain positively.

Remembering that the need for a Global Agreement arose from

the need to harmonize global efforts toward waste reduction, providing a common

legal framework that can be adapted to the realities of each country, but that

maintains a level of commitment and coordinated action at an international

level.

Its implementation will not be easy and will face various

challenges. However, the treaty will also offer significant opportunities for

innovation, development of new sustainable technologies, and the creation of

new jobs and business opportunities. We can conclude that the Global Plastics

Agreement is an important collaborative effort to mitigate environmental

impacts and promote a more sustainable future.

*Liliam Benzi is the Editor of WPO News, WPO Press &

Communication Liaison Officer and runs its own Communication & Strategy

company for the packaging industry, LDB Comunicação Empresarial ([email protected]). She was recognized ‘Packaging Professional

of the Year’ in Brazil.

[email protected] [email protected]

(+ 55 11) 99989-1597 (+ 55 11) 99989-1597

liliambenzi liliambenzi

liliam-benzi-870b771a liliam-benzi-870b771a

Liliam Benzi Liliam Benzi

Agenda

WPO at FACHPACK 2024

WPO is planning its participation at FACHPACK (www.fachpack.de) that will take place in the Exhibition Centre

Nuremberg (Germany), from 24 to 26 September. The show provides a compact and comprehensive

insight into all relevant issues in the packaging industry.

This year the big theme will be “Transition in Packaging”.

In 11 exhibition halls, around 1,400 exhibitors will showcase innovative

packaging solutions for industrial and consumer goods from a wide range of

segments. The most pressing and simultaneously most interesting topic for the

industry is the EU Packaging and Packaging Waste Directive (PPWR) that was

adopted at the end of April.

Here too, FACHPACK will provide answers to questions about

issues like recyclability, reusability and the use of recycled materials.

Reason enough to start planning your trade fair visit now so that you can be

part of the action at the end of September.

The WPO encourages everyone to take part in this event.

Registrations can be made via the link https://www.fachpack.de/en/visit with the

code A541451.

For more information about WPO participation, contact the

Secretariat, Nathália Antoniazzi by e-mail [email protected].

Around the World

Significant activities in Latvia

#1 Packaging industry conference

WPO member, the Packaging Association of Latvia (LIA – www.packaging.lv) was one of the co-organizers of the annual

packaging industry conference "Sustainable Packaging: from design to

recycling" together with Latvijas Zalais punkts (The Green Dot of Latvia /

LZP) and the Latvia University of Life Sciences and Technologies (LBTU). WPO member, the Packaging Association of Latvia (LIA – www.packaging.lv) was one of the co-organizers of the annual

packaging industry conference "Sustainable Packaging: from design to

recycling" together with Latvijas Zalais punkts (The Green Dot of Latvia /

LZP) and the Latvia University of Life Sciences and Technologies (LBTU).

The event gathered more than 150 packaging industry

specialists and several industry experts. One of the speakers was Sandra

Muižniece-Brasava, the newly elected Chairperson of the LIA Board and head of

the Technology and Knowledge Transfer Department at LBTU, who introduced the

findings of research analyzing more than 3,000 plastic packaging items

available on the shelves in Latvia regarding the problems related to packaging

efficiency and recyclability.

Other topics discussed in the conference and in the panel

discussion included promoting packaging sustainability through legislative and

regulatory updates, sustainability in the context of “EIT Food”, 100 types of

plastics – how many recycling options, new polymer materials testing laboratory

accelerating the transition to recyclable packaging.

#2 TV interview

Iveta Krauja, former longstanding Chairperson of the the

Packaging Association of Latvia (LIA – www.packaging.lv)

Board, a WPO member, gave an interview to the local ‘Greenwashing’ show. She

advised on the need of packaging and its impact on the environment, and the

possibilities of choosing more environmentally friendly packaging. Iveta Krauja, former longstanding Chairperson of the the

Packaging Association of Latvia (LIA – www.packaging.lv)

Board, a WPO member, gave an interview to the local ‘Greenwashing’ show. She

advised on the need of packaging and its impact on the environment, and the

possibilities of choosing more environmentally friendly packaging.

#3 Roundtable

The Packaging Association of Latvia (LIA – www.packaging.lv), a WPO member, took part in the roundtable

discussion with the Ministry of Agriculture and the Latvian Federation of Food

Companies on "Improving ecosystem synergies in the context of sustainable

packaging". The discussion brought Ministry representatives, industry

experts and food chain participants to discuss the challenges and possible

solutions in developing and promoting sustainable packaging in Latvia.

CAVENVASE renews its authorities for the 2024-2026 period

On May 21st, the Venezuelan Packaging Association (CAVENVASE

– www.cavenvase.org), a WPO member, celebrated its Ordinary

General Assembly in which the Board of Directors presented the results for the

year 2023, the financial statements of the organization and the elections of

authorities for 2024-2026.

Two important achievements of the Board of Directors in 2023

were highligthed: the historic milestone of the internationalization, being

accepted as WPO full member, and completing the first Boot Camp in Venezuela

about design, development and technology in packaging.

This was an advanced 120 hours course, completed in 16

weeks, with the mission to transmit theoretical and practical knowledge to the

participants. After the Camp, professionals had the skills required in

packaging design, development and technology, in order to create a competitive

and sustainable packaging project.

The newly elected Board of Directors of CAVENVASE, headed by

its first female President, Miren Urresti, confirmed its commitment with the

Venezuelan packaging industry, working on its defense and promotion, reporting

on industry advances, and training packaging specialists. CAVENVASE will

continue working for its affiliated companies, for the packaging community and,

above all, for the development of Venezuela.

Legislation in action in Ukraine

On April 17, 2024, during the Ukrainian exhibition Pack Fair

2024, WPO member, the Club Packagers of Ukraine (www.upakjour.com.ua or www.packinfo.com.ua)

held the panel ‘Legislative Acts in Action’, which was opened by Veronika

Khalaydzhi, President of the Club Packagers. She noted the importance of compliance

with laws, regulations and standards related to food packaging, as one of the

most important factors to ensure access of Ukrainian products to European

markets.

Gennady Kuznetsov (League of Food Producers) spoke about the

adoption of the law ‘On materials and objects intended for contact with food

products’ as a step towards European Integration; Volodymyr Slabiy (Ukrainian

Packaging and Environmental Coalition) presented the law project ‘On packaging

and packaging waste" and Svitlana Berzina (Living Planet) spoke about

packaging ecolabelling.

Seminar, in Greece, discussed the new regulation on

packaging and packaging waste

Wpo member in Greece, AGMPM (www.pac.gr) and the

European Organization EUROPEN, organized on May the first introductory seminar

on the final text of the new European regulation on packaging and packaging

waste (PPWR).

Marzia Scopelliti, Public Affairs Manager of Europen,

analyzed the critical chapters of the new regulation: criteria for

recyclability of all types of packaging and the possibility of circulating

packaged goods on the European market, recycled content of plastic packaging

(PCR), new mandatory labeling of packaging in transit, reduction of packaging

through horizontal bans of certain structures, re-use requirements, etc.

During the Q&A session, a significant part of the

discussion was dedicated to the availability of PCR for plastic primary

packaging of food and beverages, the approval of chemical recycling and the use

of bio-based polymers, and the tigth time frame between the publication of the

guidelines and the implementation milestones (2030).

AGMPM works and coordinates its educational actions on a

weekly basis with the Europen Organization aiming to inform and prepare Greek

companies in view of the implementation of a large number of new legislations

in the European market.

For more information about the presentation of the

representative of the Europen organization send an e-mail to [email protected].

AIP activities during ProPak Asia

WPO member in Australia and New Zealand, AIP (Australian

Institute of Packaging – www.aipack.com.au)

continues to support the ASEAN region. Reinforcing its strong partnership with

ProPak Asia, the Institute coordinated the largest educational offering of

content during the show that happened in Bangkok, from June 12-15.

In total, the Institute organized five educational events

that gathered 43 speakers from 18 countries - the Global Packaging Forum, two

mini training courses and two workshops. In addition, the AIP had a booth at

ProPak Asia to welcome visitors and also displayed the 2023 Australasian

Packaging Innovation & Design (PIDA) winners in a special area.

New President of the Italian Packaging Institute

The Assembly of members of Istituto Italiano Imballaggio (www.istitutoimballaggio.org), a WPO member,

reconfirmed Alessandra Fazio at the head of the association for the 2024-2026. The Assembly of members of Istituto Italiano Imballaggio (www.istitutoimballaggio.org), a WPO member,

reconfirmed Alessandra Fazio at the head of the association for the 2024-2026.

During the event, Alessandra Fazio retraced the goals and

results of her first tenure, focusing on the issues of communication, through

digital marketing and social channels, PR activities and the strengthening of

relations with other stakeholders in the supply chain, particularly in the

international overview.

The actions undertaken included strengthening investment in

the LinkedIn channel, a structured presence at trade fairs and a close

collaboration with the packaging associations worldwide, as WPO.

Moreover, the Italian Institute of Packaging recently joined

Europen, an important step to provide the Italian Institute with resources,

knowledge, and a platform for influence that can significantly enhance its

mission and capabilities.

Another topic closely followed by the President is the

professional training. In the last two years, the Institute recorded

interesting numbers in its training programs: 3,586 participants in more than

3,100 hours. In addition, 10 new courses and workshops were launched.

The third core topic regards the assistance to the members.

The strategy for the next two years is to be engaged on new issues such as

scientific support to advocacy activities, quality standards and

sustainability, monitoring and analysis of new market trends, and expansion of

the membership base, in particular in the less represented sectors, such as

cosmetics and luxury.

Arab StarPack honors winners in Egypt

The winners of Arab StarPack, a packaging competition

recognized by WPO and organized by its member LibanPack (www.libanpack.org), were awarded during a ceremony held in

Egypt for the ocasion of Propak MENA.

Around 300 people from Arab and African countries attended

the ceremony, including many industrialists, companies, students, and

representatives of Arab and African packaging organizations, as well as the

President of the WPO, Luciana Pellegrino, and several representatives from Arab

embassies in Egypt. The ceremony counted with the support of UNIDO and Informat

Markets.

Arab StarPack aims to raise awareness about the latest

developments and trends in the packaging sector, particularly from marketing

and sustainable development perspectives, to enable Arab companies and students

to enhance the competitiveness of the food industries and other sectors in our

region.

Soha Atallah, Director of LibanPack and Vice President

Marketing of WPO, emphasized the importance of the competition, pointing out

that it aims to stimulate creativity and perseverance. She added that the 12

companies that won the Arab StarPack competition also participated in the

WorldStar, the global competition organized by the WPO.

During the ceremony, Luciana Pellegrino, WPO President,

expressed her delight in participating for the first time in the Arab StarPack

celebration, commending the membership of Arab and African countries in the

Organization.

More than 600 students and 160 Arab companies from 08

countries – Lebanon, Egypt, Tunisia, Palestine, Jordan, Oman, the United Arab

Emirates, and Saudi Arabia - participated in the Arab Star Pack competition. To

know all the winners, visit www.arabstarpack.org.

CENEM elects new Board of Directors

On June 18, WPO member in Chile, CENEM (www.cenem.cl),

held its Annual General Assembly with voting to select the Board of Directors

for the 2024-2028 period. Pamela Pavez, Chair of the CENEM Board of Directors,

led the meeting alongside Mariana Soto, General Manager of the Corporation.

During the Assembly, the work carried out during 2023 was

reported, the Corporation's Financial Statement was presented, and the balance

for the 2023 fiscal year was approved. The Accounts Review Committee was

appointed, consisting of Erika León, General Manager of Sorepa, Jorge Fuentes,

General Manager of Siegwerk Chile, and Sara Navón, Sales Manager of Oxiquim.

A total of 12 candidates to be part of the Board of

Directors were presented, and the seven who received the most votes became part

of the Board for the next 4 years. They are: Pamela Pavez (Chilempack); Alfredo

Gili (CMPC Biopackaging Corrugados); Gino Villanueva (Amcor); Macarena Obach

(BO Packaging); Diego Vial (Sun Chemical); Fernando Álvarez (Packaging Xpert);

and Guillermo Toro (Cristoro).

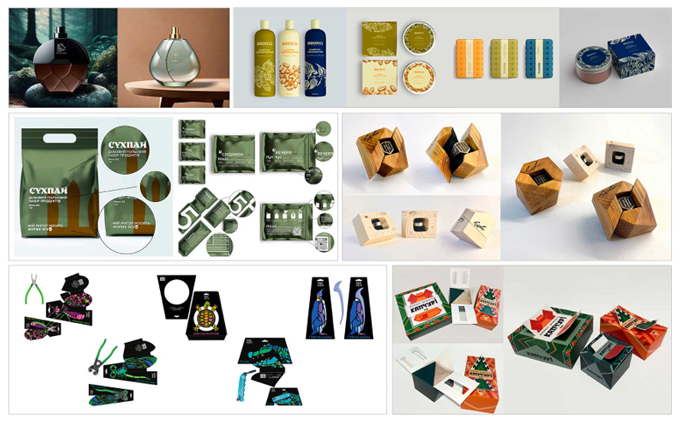

Ukrainian competition for the Best Packaging

This year, 40 samples of packages and labels, from 22

companies, from eight Ukrainian cities, took part in the local competitions

‘Ukrainian Packaging Star’, ‘Ukrainian Label’ and ‘Packaging of the Future’,

all organized by WPO member, Club Packagers of Ukraine (www.upakjour.com.ua or www.packinfo.com.ua).

Companies from Latvia also took part in the competition for

the second time. 32 packaging samples and 10 label samples developed by young

designers, from seven universities and academies, from five cities of Ukraine,

were submitted to the ‘Packaging of the Future’.

The online jury meeting was held in April and joined well-known

packaging specialists from Ukraine and abroad. The results were: 03 awards to

Gualapak Ukraine, and 02 for each one of the following companies: Univest

Marketing LLC (Fastiv city), Kaskad (Dnipro city) and TCD (Kyiv city). Other

winners of the competition represented other parts of Ukraine.

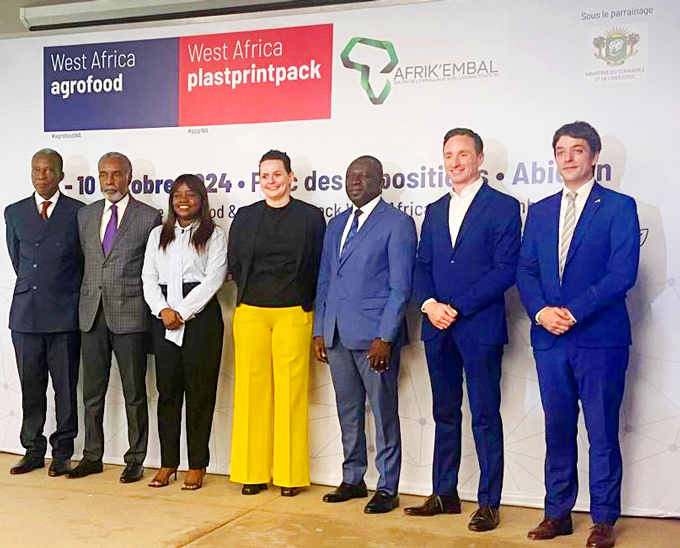

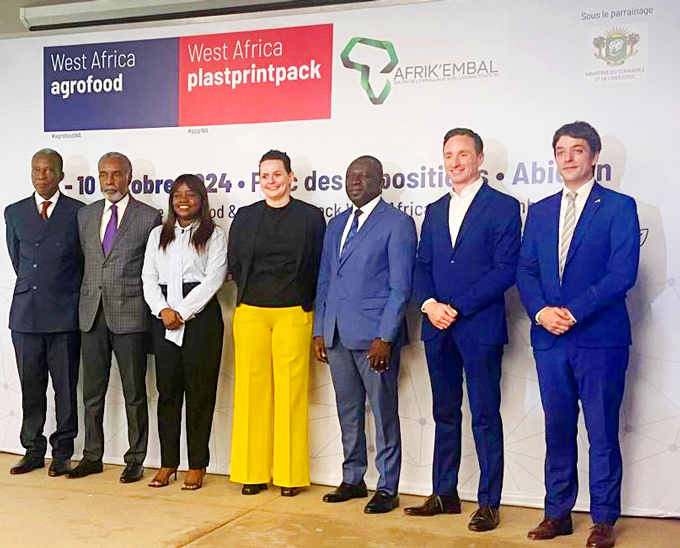

AgroFood Plastprintpack exhibition in partnership with APECI

WPO member, Association of Packaging Professionals in Côte

d’Ivoire (APECI – www.apeci.ci), is a co-organizer of the

upcoming AgroFood – PlastPrintPack West Africa exhibition (Abidjan - October

08-10), under the theme: ‘Food safety, Food waste reduction, Recycling and

Circular Economy’. The exhibition is organised

by Fairtrade Messe and APECI will develop the concept

‘AfrikEmbal’.

The idea is to showcase the entire value chain, from agro

business transformation to packaging, enabling the main local, regional and

international packaging players to meet, trade and network during the

three days show in the Ivory Coast. It is also a good opportunity to discover

global best practices in order to improve packaging developments and deliver excellent

products that are both consumers and environment-friendly.

A new cross border platform in China

WPO member in China, World Packaging Center (GPC), is proud

to introduce its new cross-border platform, the World Packaging Cloud (WPC). It

focuses on Southeast Asia and the purpose is to help China's packaging

machinery and printing equipment, packaging containers, and auxiliary material

companies to go overseas and deliver high-quality products to global packaging

users. WPO member in China, World Packaging Center (GPC), is proud

to introduce its new cross-border platform, the World Packaging Cloud (WPC). It

focuses on Southeast Asia and the purpose is to help China's packaging

machinery and printing equipment, packaging containers, and auxiliary material

companies to go overseas and deliver high-quality products to global packaging

users.

Well done in the ScanStar!

WPO congratulates its members in the Nordic region - Sweden,

Finland, Norway, Denmark and Iceland - for the record of entries in the

ScanStar (www.scanstar.org) packaging competititon that

qualifies for the WorldStar Awards, the WPO global packaging award.

The jury meeting was hosted by WPO Vice President

Governance, Magnus Sidling, and member from Sweden, Mikael Gällstedt.

From the Board

From Thailand to Cuba!

WPO Global Ambassador, Silvio Colombo, from Argentina, flew directly from Propak Asia, in Bangkok, to Havana, to be the trainer in the packaging training course organized by WPO member from Cuba, the National Center for Containers and Packaging (CNEE).

As part of WPO packaging training programs, coordinated by Vice President of Education, Kofi Essuman, there are still 03 more scheduled to the second part of 2024: Kenya, Italy and Philippines. For more information, visit WPO webpage www.worldpackaging.org.

WPO visit to IAEA facilities

On June, WPO held a meeting, in cooperation with UNIDO (www.unido.org),

at the International Atomic Energy Agency (IAEA – www.iaea.org)

facilities in Seibersdorf (Austria). On that occasion, the WPO delegation got

to know the Food Safety and Control laboratory and discussed the opportunities

for future cooperation between the organizations.

WPO was represented by its General Secretary, Johannes

Bergmair, and the Secretariat, Nathália Antoniazzi, that met Aleksa Mirkovic,

from UNIDO, and Christina Vlachou and Giselle Ruiz de Neumayr, from IAEA.

Well done Nerida!

WPO congratulates its Vice President Sustainability &

Save Food, Nerida Kelton, that was awarded with the inaugural Hall of Fame

Women in Packaging for Australia and New Zealand. She was recognized for being

a “trailblazer and mentor for women in the region”.

WPO member, the Australian Institute of Packaging (AIP – www.aipack.com.au) supported the inaugural Women in Packaging

Awards powered by the local publication, PKN Packaging News.

Future plans with Hispack, in Spain.

Also on June, WPO received in its headquarters in Vienna,

the visit of the representatives of Market AAD, a consultancy company that

supports Hispack (www.hispack.com), in the organization of

conferences and content events at the packaging show in Spain.

WPO General Secretary, Johannes Bergmair, hosted Ricard

Madurell and Adrià Llacuna. On the occasion, they discussed WPO's future

contribution and cooperation to the next edition of Hispack.

Education

Packaging program in UK

WPO member in UK, IOM3 (www.iom3.org), offers

a range of courses to help upskill those in the packaging industry. The

courses cover a wide range of topics and are suitable for those just starting

out in the industry or simply wanting to expand their knowledge, or to those

wishing to undertake learning in specific areas of packaging technology.

Many of our courses are available in person or as online

distance learning, and lead to recognised qualifications from PIABC. Online

learners can start our online PIABC Level 3 Certificate in Packaging and EQUIPT

courses at any time.

Please note that the note that the next intake for our PIABC

Level 5 Diploma in Packaging Technology blended learning course is 23 October

2024.

For a full list of packaging technology and packaging

industry courses, go to: https://bit.ly/iom3packaging.

News from Corporate Partners

TNA announces ‘Packed with Purpose’ initiative to support

children’s education in disadvantaged communities

In an unprecedented event to raise funds to enhance the

lives of children in disadvantaged communities, WPO Corporate Partner, TNA

Solutions (www.tnasolutions.com), presents ‘Packed with

Purpose’, a unique giveaway that gives entrants an unbelievable 1 in 200 chance

to win the tna robag® worth USD 200,000. The initiative is under the company´s

philanthropic arm, the Nadia and Alf Taylor Foundation.

To participate, the first 200 people will have the

opportunity to donate the equivalent to USD 1,500 or more, after which the

entries will be closed and 100% of the proceeds will be given directly to fund

deserving projects.

The grand prize draw will take place on 25 July 2024, and

the winner will receive the world’s fastest VFFS solution, the tna robag®. The

equipment offers unrivalled speeds of up to 250 bags per minute combined with

wastage as low as 0.1%. It provides superior flexibility and enhanced

serviceability for maximum up-time, and bags just about any type of food

application faster and more efficiently than anyone else. The grand prize draw will take place on 25 July 2024, and

the winner will receive the world’s fastest VFFS solution, the tna robag®. The

equipment offers unrivalled speeds of up to 250 bags per minute combined with

wastage as low as 0.1%. It provides superior flexibility and enhanced

serviceability for maximum up-time, and bags just about any type of food

application faster and more efficiently than anyone else.

Dave Everett OAM, CEO of the Nadia and Alf Taylor

Foundation, said: “At a 1 in 200 chance, the odds of winning the tna robag® are

unbelievable! The important point here is that by donating, you are making a

big difference to underprivileged children around the world who would otherwise

go without the chance of a decent education. There is no downside that we can

see, just a chance to contribute directly to a great cause and win TNA’s market

leading packaging system in the process.”

If the target is not reached, the Foundation will refund the

donations.

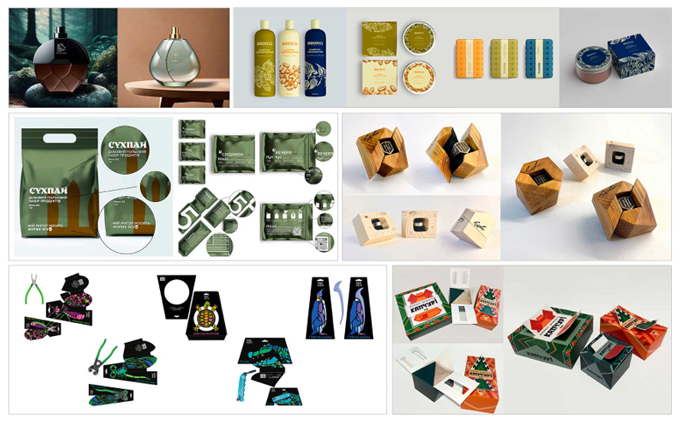

Worldstar Awards

WorldStar Award and WorldStar Student

Ceremony 2024 celebrated the global packaging excellence in Bangkok

WPO organized the prestigious WorldStar

Awards and WorldStar Student Award Ceremony and Gala Dinner during ProPak Asia

2024, on June 15. The event was hosted by the show organizer, Informa Markets

Asia, and was attended by around 300 packaging professionals from 42 countries

and WPO Board Members, counting as well with Informa Markets and UNIDO

representatives. Once again, WorldStar and WordStar Student entries showcased

the pinnacle of innovation and dedication in the packaging industry.

The evening kicked off with an authentic

cultural performance, celebrating the rich heritage of Thai culture. Besides

the 90 winners present in the Ceremony, representing 77 companies across 31

countries, the night also awarded two winners of WorldStar Student, from Ghana

and the USA, and the Lifetime Achievement Award in Packaging, delivered to

Gyorgy Viskel, from Hungary, honoured for his lifelong contributions to the

packaging industry.

The WorldStar Special Categories were also

acknowledged during the night as the best packaging innovations in

Sustainability, Packaging that Saves Food, and Marketing. Last but not least,

the President’s Award was presented by WPO President, Luciana Pellegrino,

celebrating the most innovative and impactful packaging solution.

Luciana Pellegrino expressed her pride and

vision for the future stating: “The WorldStar Awards ceremony celebrates the

best of the best in packaging innovation from around the globe. And a special

evening like this, gathering the global packaging community, strengthens our

industry and inspires us push collaboration and solutions for a greater

positive impact.”

Soha Atallah, WorldStar Coordinator and WPO

Vice President for Marketing also shared her excitement, saying: “It is an

honour to LibanPack to organize the WorldStar, on behalf of WPO, for the third

consecutive year. Seeing the pride and the bright shine in the eyes of the winners

makes all the efforts worthwhile. This year, we celebrated the 56th edition of

WorldStar and we are thrilled to have it in the vibrant city of Bangkok, during

Propak Asia.”

Both Luciana Pellegrino and Soha Atallah

expressed their appreciation for Informa Markets team for hosting WorldStar

Ceremony and for their warm hospitality for WPO activities – Board Meeting,

Working Groups and Executive Meeting – for a week (June 10-15), during ProPak

Asia.

The complete list of WorldStar Winners is

available on WorldStar website www.worldstar.org and

the list of WorldStar Student is available at www.worldstarstudent.org.

The new edition for Worldstar 2025 was

opened for entries on July 10, 2024. For more information

on WorldStar Awards, contact the Coordinator, Soha Atallah, by e-mail [email protected].

Trends Report

WorldStar Awards and WorldStar Student Packaging Trends

Report is available for download!

The latest edition of the WPO Packaging Trends Report, based

on the winners of WorldStar Awards 2024 (www.worldstar.org) and

WorldStar Student (www.worldstarstudent.org)

2024, is available for free download in WPO webpage www.worldpackaging.org.

The document includes, among other details, the global

packaging trends for 2024:

- Consumer Awareness & Preferences

- Single-Use Plastics Regulations

- Extended Producer Responsibility

- Recycled Content Requirements

- Labeling Legislation

- Design for Recovery

- Substance Restrictions

The Report also analyzes each WorldStar category and

connects them with the main trends identified in the winning packages. The

Packaging Trends Report was produced by WPO Press & Communication Liaison

Officer, Liliam Benzi.

Special Interview – Pierre Pienaar

The importance of being the first Lifetime

CPP in Australasia

The AIP (Australian Institute of Packaging

– www.aipack.com.au), a WPO member, congratulates the recipient

of the first Lifetime Certified Packaging Professional in Australasia, Pierre

Pienaar MSc FAIP, FIPSA, CPPL, Education Director, AIP and former WPO President.

Let´s hear what he has to say about the CPP

program that has been accepted as the global recognition as a packaging

professional and has become the leading mark of excellence internationally, and a must-have recognition of industry proficiency and

achievement for packaging professionals.

1. How long have you been in the

industry? What are your areas of expertise?

Pierre: I commenced in the industry in

1984 after studying pharmacy and joining a large pharmaceutical manufacturer.

After a year of doing drug analysis an offer came up to become involved in

packaging. I jumped at the opportunity of getting out of the laboratory and

venturing into the world of packaging. I was asked by the CEO to find a

university somewhere in the world to do a post graduate degree in Packaging. I

found Brunel University in London where I completed a Master’s Degree in

Packaging Engineering.

It is because of my undergraduate studies

that I have developed an affinity for pharmaceutical packaging. I enjoy

packaging problem solving in a production environment because in my early years

in pharma where I spent 6 years in the manufacturing of liquid, parentals and

solids and where the packaging was diverse and there was lots to learn in

packaging when it came to output on the diverse filling machines. It was during

these years in production that I completed a Master’s Degree in Production from

University of Hertfordshire, UK.

2. What made you originally

apply for the Certified Packaging Professional (CPP) Designation?

Pierre: Whilst involved in the WPO as Vice

President Education, I wanted the WPO to have an international recognised

accreditation because we had no idea of the various qualifications of the wide

variety of people involved in the WPO. At that time, the WPO President, Tom Schneider,

tasked me to find such a reputable accreditation that would fit with the needs

of the WPO and was internationally recognised. At the same time, the AIP was

also in discussions with IoPP (Institute of Packaging Professionals – www.iopp.org),

WPO member in the USA, to launch the program into Australasia.

WPO used the AIP development of the program

as a test case for how it could work for the rest of the world. The WPO program

was borne out of the AIP program. At this early stage, the AIP became involved

in supporting the development of the WPO program and they became first

association to offer the CPP outside of the USA. I attained my CPP through the

AIP and I became the first person to become a CPP in Australasia. The AIP had

the tenacity to become the first association to offer the program for

Australasia and they now have many CPP's in the region and support those around

the world to undertake the designation.

3. Why was it so important for

you to attaining the CPP designation?

Pierre: It is important that when the

global packaging community comes together, we can easily recognise other

professionals that are equally qualified in the various disciplines in

packaging. The CPP designation gives us all a sense of belonging to a bigger

global community.

Recognition however must go to the AIP for

all of their hard work in becoming the first association outside of the IoPP to

offer the program and for taking the lead in the WPO Members. The AIP supports

the WPO CPP program and works with many people around the world today to help

guide them to attain the designation. In fact, the General Secretary of the WPO,

Johannes Bergmair, undertook his CPP through the AIP.

4. How important is the CPP

designation for the greater recognition of people in the packaging industry?

Pierre: It is the ultimate and only method

of ensuring that you are recognised internationally in the packaging industry,

through this CPP accreditation program. The CPP is also recognised in over 64

WPO Member countries which will help you to look for jobs overseas. Just

knowing this is so encouraging and inspiring.

5. Were there any new learnings or

takeaways that you gained from the experience?

Pierre: It has reminded me just how

diverse packaging really is, all encompassing, where the left and right brain

is required to solve the myriads of options and opportunities. It is a field

where on-going studying and learning, be that in conferences, classroom,

reading, discussions, webinars, seminars are all truly necessary, so as to stay

abreast of developments.

6. What does it feel like to be the first

Lifetime CPP in Australasia?

Pierre: If it inspires others to gain

their CPP in packaging, then it has been worthwhile. Like anything there always

has to be a first, I just happened to be in the right place and at the right

time and nudged at the beginning by Nerida Kelton to attain the CPP

designation.

7. What advice would you offer anyone in

the industry looking to become a Certified Packaging Professional?

Pierre: What has driven me is to ensure

that growth in education persists. It is encouraging to witness this

enhancement and growth of the packaging industry over these ensuing years.

This highly regarded Certified Packaging

Professional (CPP) program is really gaining momentum across all nations in the

packaging professional space. The AIP is intentional about education and

ensuring that it remains current giving the industry the advantage of access to

cutting-edge packaging developments globally, and the CPP program is part of

that education.

If your intention is to remain in the packaging

industry, and you want to ensure on-going learning, then the CPP program is for

you. It certainly gives you a sense of belonging and a great personal sense of

achievement.

Attaining the CPP designation is an

excellent investment in your professional development and the credential

defines the packaging professional and allows organisations to seek out and

hire the right professional based on verified knowledge, skills and industry

contributions. Using the CPP program to assess and evaluate one’s professional

competency validates you as internationally proficient as a packaging

professional; a cut above your peers.

Special Article – Sustainability

Standout sustainable packaging at Anuga

FoodTec 2024

By Nerida Kelton*

For the first time, WPO decided to exhibit

and participate in three speaking sessions during Anuga FoodTec, a 04 days show

that joined almost 40,000 people, from 133 countries, in Cologne (Germany). On

the occasion, I had the opportunity to visit some of the exhibition stands,

talk to a number of exhibitors and see what is new, innovative, and intuitive.

I was particularly looking for packaging

that is recycle ready, offers improvements to packaging to provide lower

environmental impacts, new advancements in paper and renewable materials, and any

save food packaging design. And here is the result of my search!

SIG Alu Free cartons

SIG Alu Free cartons are an aseptic carton

with no aluminium layer. The carton is FSC certified paperboard, is fully

recyclable and produced with 100% renewable energy. The SIG Alu free carton has

a carbon footprint up to 27% lower than standard SIG packaging material, thanks

to a unique composite with no aluminium layer. It is designed for liquid dairy

products such as plain white UHT milk, cream, and other oxygen-insensitive

products. The carton is made from up to 82% renewable paperboard, with

ultra-thin polymer layers to contain and protect products over long periods of

time without the need for refrigeration. SIG Alu Free cartons are an aseptic carton

with no aluminium layer. The carton is FSC certified paperboard, is fully

recyclable and produced with 100% renewable energy. The SIG Alu free carton has

a carbon footprint up to 27% lower than standard SIG packaging material, thanks

to a unique composite with no aluminium layer. It is designed for liquid dairy

products such as plain white UHT milk, cream, and other oxygen-insensitive

products. The carton is made from up to 82% renewable paperboard, with

ultra-thin polymer layers to contain and protect products over long periods of

time without the need for refrigeration.

SIG also recently added the option to link

to 100% forest -based renewable materials via a mass-balance system. The SIG

Alu free carton is another step to remove aluminium form aseptic cartons but

still maintain shelf life and barrier for products.

www.sig.biz

Sea6 Energy developing seaweed-based films

Seaweeds, characterised by their efficient

utilisation of solar energy and minimal resource requirements, offer a

promising solution to address the pressing challenges of resource scarcity and

environmental degradation. Seaweeds, characterised by their efficient

utilisation of solar energy and minimal resource requirements, offer a

promising solution to address the pressing challenges of resource scarcity and

environmental degradation.

Headquartered in Bangalore, Sea6 Energy

believes that there is a critical need to design innovation strategies to meet

the escalating demand for raw materials, particularly within the packaging

industry.

Sea6 Energy are developing seaweed based,

compostable films that can be used for packaging of FMCG goods and fast foods.

These films, when discarded into the environment, will compost in a few months

and are available in Food and Non-food grades.

The utilisation of seaweed biomass extends

beyond traditional boundaries, encompassing the production of bio stimulants

for agriculture and horticulture, food and feed ingredients, and the

development of innovative biomaterials tailored for the packaging industry.

Sea6 Energy is actively engaged in research and development efforts to

formulate seaweed-derived biomaterials such as coatings, and extrusion

compounds for flexible films and rigids. These biomaterials offer several

advantages, including biodegradability, renewability, and reduced environmental

impact, positioning them as sustainable alternatives to traditional packaging

materials. The commercialisation of first materials is targeted within the next

12 months. I look forward to watching Sea6 Energy developments in the future.

https://www.sea6energy.com/solutions/bio-plastics/

PaperBoard – formable paper by Multivac

The PaperBoard series has been designed to

eliminate single use plastics, reduce the use of plastics and improve

recyclability of the packs. The material can be run on packaging systems in the

form of rolls, pre-cuts, or trays. Paper fibre and cardboard composites with

different grammages and functional layers are available. The use of functional

layers makes it possible to produce paper-based packs that meet the barrier

property requirements of the respective product. The PaperBoard series has been designed to

eliminate single use plastics, reduce the use of plastics and improve

recyclability of the packs. The material can be run on packaging systems in the

form of rolls, pre-cuts, or trays. Paper fibre and cardboard composites with

different grammages and functional layers are available. The use of functional

layers makes it possible to produce paper-based packs that meet the barrier

property requirements of the respective product.

What I personally like about the PaperBoard

series is that the design is a step ahead of many other available solutions in

the market for separability of the components for recycling. Many consumers get

frustrated by some of the packs on the market as they can’t easily separate the

film from the paper. This in turn means that the separable components end up in

the wrong disposal bin and the pack that has been promoted as reducing single

use plastic and being more sustainable is not meeting sustainable design

standards.

The PaperBoard design however does separate

easily as I tested multiple packs. The design features are intuitive and ensure

that the paper and the film can in fact be easily and quickly separated by a

consumer.

www.multivac.com

G. Mondini Paper2Skin

Another paper-based solution that I saw on

the G.Mondini stand was Paper2Skin which is a unique and innovative paper top

skin web technology designed to take packaging to the next level. The pack has

been designed to eliminate single use plastics, use less material at the start

and ensure that the materials can be separated and recycled easily. Another paper-based solution that I saw on

the G.Mondini stand was Paper2Skin which is a unique and innovative paper top

skin web technology designed to take packaging to the next level. The pack has

been designed to eliminate single use plastics, use less material at the start

and ensure that the materials can be separated and recycled easily.

The Paper2Skin material is FSC/PEFC certified,

is designed to be able to separate the components for recyclability and is

easily openable and separable for the consumer. The pack offers a uniquely

shaped window and the laser cutting of paper allows each brand to be able to

create several window shapes depending on the product shape and size.

https://www.gmondini.com/

Anuga FoodTec has always been on my bucket

list of global trade shows that I have wanted to see, and it did not

disappoint. Unfortunately, I didn’t get to see as many exhibition stands as I had

wanted as it is a very large exhibition with thousands of stands.

I have no doubt that there were many other

innovative packaging designs on display that I missed but the ones I have

mentioned are just some that I wanted to share with you.

If you are planning to attend the next

edition of Anuga FoodTec on the 23rd to 26th of February 2027 I would recommend

that you allow at least two days to walk around the show. I also look forward

to returning to Anuga FoodTec in 2027 to see even more advancements in

sustainable packaging and recycle ready packs. Imagine what we will see in

three years!

*Nerida Kelton is Executive Director of WPO

member AIP (Australian Institute of Packaging – www.aipack.com.au) and WPO Vice President Sustainability &

Save Food [email protected].

Special Article – TNA

TNA revolutionises potato product supply

for the Egyptian Army

TNA Solutions (www.tnasolutions.com), a WPO Corporate Partner, has

implemented a ground-breaking project for the Egyptian Army. Tasked by the

Egyptian National Services Projects Organisation (NSPO) in 2020, TNA has

delivered two cutting-edge complete production lines for potato products. Specifically

designed for Hash Browns and Rosti, the first line is capable of producing two

metric tonnes per hour, while the second line, dedicated to French Fries,

wedges and disks, produces up to 10 metric tonnes per hour.

Production efficiency is maximised as TNA

provides every element of the production process, from potato washing and

de-stoning to packing products in bags. In addition, TNA’s unrivalled expertise

has enabled the integration of state-of-the-art distribution and arctic

packaging systems, specifically tailored for frozen potato products.

In collaboration with Optima Solutions,

formerly Getec Partners LLC, TNA secured this prestigious contract to support

the Egyptian Ministry of Defence in achieving self-sufficiency in meeting the

needs of the armed forces, the local markets, and export products. TNA’s

industry-leading reputation for delivering exceptional projects solidified its

position as the chosen partner. The project was a true testament to the

dedication of TNA’s solutions specialists and global team of experts.

The Egyptian President, Abdel Fattah

El-Sisi, championed an inaugural ceremony at the factory, at which he

emphasised unwavering commitment to advancing the industrial landscape in

Egypt, simultaneously advocating for the preservation and protection of the

environment and the implementation of eco-friendly factory designs.

Thiago Roriz, TNA’s Chief Operations

Officer, was invited to address the gathering. On behalf of TNA’s founders,

including co-founder & Director, Nadia Taylor, who takes immense pride in

her Egyptian heritage, Thiago expressed heartfelt gratitude to the President

and reaffirmed TNA's commitment to supporting the venture and sharing its

unparalleled expertise in potato production: “TNA is a leading provider of potato

production lines – having supplied more than 14,000 systems across 120

countries globally. We are proud to have an opportunity to support this project

and to offer expertise in food processing and packaging to deliver the highest

possible quality.”

TNA’s cutting-edge machinery,

state-of-the-art technology and extensive process experience empowered the

company to deliver the two complete lines on schedule, ensuring the efficient

production of premium worldwide quality products while adhering to energy

consumption, CO2 emissions and other sustainability related goals. Thiago

continued: “TNA is immensely proud and honoured to be an integral part of this

project. We extend our sincere appreciation to President El-Sisi, the Egyptian

government, and our trusted strategic partner, Optima Solutions, for making

this resounding success possible.”

The completion of both production lines in

June 2023 marks the beginning of a transformative era. Discussions are already

underway to expand operations to include new potato products, sweet potatoes

and the processing of various agricultural products. As

TNA continues to spearhead innovation, its new solutions are set to reshape the

potato processing industry, improving efficiency, quality and sustainability.

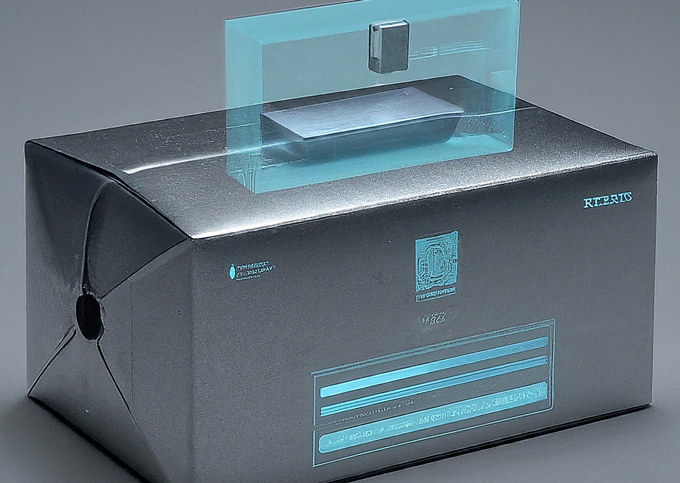

Special Article

Smart packaging technologies: enhancing product

traceability, consumer engagement, and supply chain transparency.

By Jopack, WPO member in Jordan*

Smart packaging, an innovative intersection

of packaging and technology, is transforming how products are tracked,

consumed, and managed across the supply chain. Incorporating NFC tags, QR

codes, and sensors into packaging offers sophisticated solutions that improve

product authenticity, consumer interaction, and operational transparency. This

paper delves into the mechanisms, benefits, and implications of these

technologies in modern packaging systems.

Mechanisms of smart packaging technologies

NFC Tags NFC Tags

NFC technology allows for wireless

communication between the packaging and a smartphone or NFC reader. NFC tags

embedded in packaging can store information such as production dates,

ingredient sourcing, and logistical data. When consumers scan these tags with

their smartphones, they gain instant access to this information, thereby

enhancing product authenticity and transparency.

QR Codes QR Codes

QR codes are two-dimensional barcodes that

can be scanned by a smartphone to retrieve data stored within the code. These

codes can link consumers to websites that provide detailed product information,

including manufacturing processes, shipping history, and storage conditions. QR

codes serve as a bridge between physical products and digital information,

facilitating comprehensive product tracking and consumer engagement.

Sensors Sensors

Sensors integrated into packaging can

monitor and report real-time conditions such as temperature, humidity, and

light exposure. These sensors help in maintaining the quality and safety of

perishable goods by alerting stakeholders to any deviations from optimal

storage conditions. Sensor data can be transmitted to supply chain managers,

ensuring proactive measures are taken to prevent spoilage and maintain product

integrity.

Benefits of smart packaging technologies

Enhanced product traceability

Smart packaging technologies enable precise

tracking of products from production to consumption. NFC tags and QR codes

provide a digital trail that can be monitored in real-time, ensuring that

products reach consumers in the intended condition. This traceability is

crucial for quality control, inventory management, and regulatory compliance.

Improved consumer engagement

By offering interactive experiences, smart

packaging technologies increase consumer engagement. NFC and QR code-enabled

packaging can provide access to promotional content, usage instructions, and

loyalty programs. This not only enhances the consumer experience but also

strengthens brand loyalty and drives repeat purchases.

Supply chain transparency

Smart packaging contributes to greater

transparency within the supply chain. Sensors provide real-time data on

environmental conditions during transit, allowing companies to ensure that

products are handled correctly. This transparency helps in identifying and

addressing issues promptly, reducing waste and improving overall supply chain

efficiency.

Challenges in implementing smart packaging

Cost implications

The integration of smart technologies into

packaging can be costly. The initial investment in NFC tags, QR codes, and

sensors, along with the necessary infrastructure for data management, can be

significant. These costs may be prohibitive for smaller companies, limiting the

widespread adoption of smart packaging technologies.

Technical and logistical barriers

Implementing smart packaging requires

overcoming technical challenges related to data security, interoperability, and

scalability. Ensuring that the technology works seamlessly across different

platforms and environments is critical for its success. Additionally,

logistical challenges such as maintaining the readability of QR codes and NFC

tags under various conditions must be addressed.

Future directions

The future of smart packaging looks

promising, with ongoing advancements in the Internet of Things (IoT) and

artificial intelligence (AI) poised to further enhance its capabilities. Emerging

technologies such as blockchain can complement smart packaging by providing

immutable records of product history, thereby further improving traceability

and trust. Moreover, as the cost of smart technologies decreases, their

adoption is expected to become more widespread, driving innovation and

efficiency in the packaging industry.

Conclusion

Smart packaging technologies represent a

significant leap forward in the packaging industry, offering innovative

solutions that enhance product traceability, consumer engagement, and supply

chain transparency. While challenges related to cost and implementation exist,

the benefits of smart packaging are substantial and

far-reaching. As technology continues to evolve, smart packaging is set to play

a pivotal role in shaping the future of product management and consumer

interaction.

*Jopack (Jordan National

Packaging Center – www.jopack.org) is a WPO member.

For more information, contact Sarah Hudaib, Project Manager & Testing

Technician, by e-mail [email protected].

Special Article

Packaging for e-commerce: balancing protection,

cost, and sustainability

By Jopack, WPO member in Jordan*

E-commerce has transformed the retail

landscape, offering consumers convenience and a wide range of products at their

fingertips. However, this shift has also brought new challenges in packaging.

Unlike traditional retail, e-commerce requires packaging that can withstand the

rigors of shipping while maintaining cost-effectiveness and environmental

sustainability. This article delves into the critical aspects of e-commerce

packaging, exploring strategies to achieve an optimal balance between

protection, cost, and sustainability.

Challenges in e-commerce packaging

1. Protection

Impact resistance – Products sold online must

be packaged to withstand various physical stresses during transit, including

handling, stacking, and transportation. Insufficient protection can lead to

product damage, resulting in customer dissatisfaction and increased return

rates.

Environmental factors – E-commerce packages

are exposed to varying environmental conditions such as temperature

fluctuations and humidity. Packaging materials must be chosen to protect

products against these factors, ensuring they arrive in perfect condition.

2. Cost

Material costs – The choice of packaging

materials significantly impacts the overall cost. While premium materials offer

better protection, they can be expensive. Finding a cost-effective solution

that does not compromise on quality is essential for maintaining profit

margins.

Shipping costs – E-commerce packaging must

also consider dimensional weight pricing. Bulky or heavy packages incur higher

shipping costs, making it crucial to design packaging that is both lightweight

and compact without sacrificing protection.

3. Sustainability

Environmental impact – With increasing

consumer awareness of environmental issues, there is a growing demand for

sustainable packaging solutions. Businesses must balance the need for

protective packaging with the imperative to reduce their environmental footprint.

Regulatory compliance – Various regulations

and guidelines mandate the use of sustainable materials and practices in

packaging. Companies must stay compliant with these regulations while meeting

their operational needs.

Opportunities in e-commerce packaging

1. Innovative materials

Biodegradable and recyclable materials – Innovations in materials science have led to the development of biodegradable

and recyclable packaging materials. These options reduce environmental impact

while providing adequate protection for products.

Lightweight alternatives – New lightweight

materials, such as molded pulp and air pillows, offer protection without adding

significant weight. These materials can help reduce shipping costs while

maintaining product integrity.

2. Smart packaging

Track and trace – Smart packaging

technologies, such as RFID tags and QR codes, allow for real-time tracking of

shipments. This enhances transparency in the supply chain and improves customer

satisfaction by providing accurate delivery information.

Temperature control – For perishable goods,

smart packaging with temperature sensors can monitor and maintain optimal

conditions, ensuring product quality upon arrival.

3. Customization and branding

Personalized packaging – E-commerce provides

an opportunity for businesses to use packaging as a branding tool. Customized

packaging that reflects the brand’s identity can enhance the unboxing

experience and build customer loyalty.

Eco-friendly branding – Emphasizing

sustainability in packaging design can attract environmentally conscious

consumers. Using recycled materials and highlighting eco-friendly practices in

branding can differentiate a company in the competitive e-commerce market.

Strategies for balancing protection, cost,

and sustainability

1. Design optimization

Minimalist design – Adopting minimalist

design principles can reduce material usage and waste. This involves designing

packaging that uses the least amount of material necessary while still

providing adequate protection.

Right-sizing – Right-sizing packaging to fit

the product snugly minimizes excess space, reducing the need for additional

protective fillers and lowering dimensional weight for shipping.

2.

Material selection

Hybrid solutions – Combining different

materials can optimize the balance between protection, cost, and

sustainability. For example, using a sturdy outer layer with a biodegradable

inner layer can offer both protection and environmental benefits.

Recycled content – Incorporating recycled

content in packaging materials reduces the demand for virgin resources and

minimizes environmental impact.

3. Process improvements

Automation – Implementing automated packaging

solutions can increase efficiency and reduce labor costs. Automated systems can

also ensure consistent quality and reduce material waste.

Return packaging – Designing packaging that

can be easily reused for returns can improve sustainability and customer

convenience. Returnable packaging solutions reduce the need for additional

materials and lower overall environmental impact.

Conclusion

Packaging for e-commerce presents unique

challenges that require a careful balance of protection, cost, and

sustainability. By leveraging innovative materials, smart technologies, and

optimized design strategies, businesses can meet these challenges head-on. As

the e-commerce market continues to grow, the importance of sustainable and

cost-effective packaging solutions will only increase. Companies that

prioritize these aspects will be well-positioned to succeed in the evolving

retail landscape.

*Jopack (Jordan National

Packaging Center – www.jopack.org) is a WPO member.

For more information, contact Sarah Hudaib, Project Manager & Testing

Technician, by e-mail [email protected].

Special Article

Food packaging for aerospace

By B R Guduri1 and A Banerjee2*

Introduction

With the increasing prevalence of

commercial space flight and the prospect of future travels to Mars, many individuals

are embarking on long-duration space missions. However, the expedition exposes

them to medical issues that arise due to the conditions of the space

environment. Therefore, selecting appropriate packaging in this particular

setting is crucial owing to several aspects like weight limitations,

preservation requirements, ensuring the safety of nutrients in microgravity

conditions, and achieving waste reduction goals. The weight factor is crucial

for minimizing energy consumption [6], while preservation is essential for

maintaining freshness over a more extended period and ensuring the desired

nutritional content. Space organizations and academics must thus find and

strategize for appropriate food packing due to the demanding and isolating

circumstances of the demanding and isolated environment. With the increasing prevalence of

commercial space flight and the prospect of future travels to Mars, many individuals

are embarking on long-duration space missions. However, the expedition exposes

them to medical issues that arise due to the conditions of the space

environment. Therefore, selecting appropriate packaging in this particular

setting is crucial owing to several aspects like weight limitations,

preservation requirements, ensuring the safety of nutrients in microgravity

conditions, and achieving waste reduction goals. The weight factor is crucial

for minimizing energy consumption [6], while preservation is essential for

maintaining freshness over a more extended period and ensuring the desired

nutritional content. Space organizations and academics must thus find and

strategize for appropriate food packing due to the demanding and isolating

circumstances of the demanding and isolated environment.

Literature Review and Discussion

Literature shows

that technological advancements have revolutionized packaging techniques,

particularly for the space environment. The development is necessary because of

the unique characteristics of the space environment, such as microgravity,

which impact astronauts' ability to taste and smell [6]. Occasionally, space

organizations have acknowledged the potential benefits of using packaging

techniques that are lightweight, small, and durable enough to endure the

rigours of space flight [2]. Packing materials must be developed to decrease

weight and consider recycling or reusability to reduce the overall bulk of the

packaging. Moreover, the packaging structure should be meticulously constructed

to minimize the risk of microbial contamination. Space equipment must endure

rigorous circumstances such as high temperatures, radiation, and vacuum,

necessitating packaging that can withstand these harsh environments. The table

below presents an overview of food-packing techniques used in space exploration

missions.

Type of food |

Comments |

Examples |

Bite-size food |

Easy to consume and does not require anypreparation packed in flexible packaging |

Nuts, dried fruits, andgranola bars |

Rehydratable food |

Dehydrated and requires water to be addedbefore consumption packed in plastic

containers |

Soups, stews, and pasta dishes |

Thermostabilized food |

Cooked and then sealed in a container

suchas retort flexible pouches or cans to

prevent contamination |

Canned or retort pouch foods |

Intermediate moisture food |

Moisture content - 15% to 50%. Preserved using drying, salting, or

adding preservatives in flexible packaging |

Jerky and dried fruits |

Irradiated food |

Exposed to ionizing radiation to killbacteria and other microorganisms in cans |

Meat, poultry, and spices |

The Russian space program uses cans and

tins for food packaging. Moreover, in order to heat these packages, they use

electro-resistive methods [1]. However, NASA uses retort pouches or freeze-drying

[8]. The organization closes its space food in hermetically sealed canisters

made to fit tightly into trays, and the canisters themselves are tiny. There

are straps on the bottom of the trays to enable their fixing in a specific

position on a fixed object. Furthermore, the trays have provisions for holding

a beverage pouch or utensils in the microgravity environment. Laminated films

and flexible pouches decrease the weight and size of packing materials, whereas

self-heating food packaging uses a chemical process to warm the food [3]. Space

packaging also embraces materials that prevent the ingress of oxygen and

moisture to avoid oxidizing the food.

Modified atmosphere methods are used to

package rehydratable and bite-sized foods. Before the final seal, each package

undergoes three nitrogen flushes and is sealed under a vacuum of 21 to 29

inches of Hg. Metalized sheets and laminates protect food from radiation and

temperature variations [4]. Space missions utilized bite-size food cubes in

Gemini. They also used spoon-bowl rehydratable packages and thermostabilized

flex pouches in Apollo. Tear-top commercial food cans and polyethylene beverage

containers were essential in Skylab. These missions examine packaging

limitations and compare various food packaging materials.

After the Space Shuttle Era, NASA entered

the 'Space Station Era' with the International Space Station (ISS) in 2011. The

transition witnessed NASA using a packaging method for rehydratable and

bite-size foods. The packaging comprised five layers: nylon, ethylene vinyl

alcohol, polyethylene tie layer, linear low-density polyethylene, and aluminum

foil laminate. It was vacuum sealed and overwrapped with aluminum foil before

being transported to the ISS. Beverages were protected using foil and plastic

laminations to give them a more extended shelf period. NASA also had

thermostabilized and irradiated foods in commercial pouches [4], which they

would then package together.

Future Scope

Space food packaging has immeasurable

prospects for the future. The requirement for packaging solutions that can be

sustainable, beneficial to the ecology, and recyclable or reusable in space has

been on the rise [1]. Hence, various organizations involved in space research,