|

President’s Word

A new year full of possibilities!

Luciana Pellegrino

President of WPO

We say goodbye to 2024 with a very good feeling of mission

accomplished, and the certainty that the year was explored in its best! The

numbers say for itself:

- 17 trade shows around the globe;

- our 1st conference at UNIDO’s headquarter in Vienna;

- 03 round tables with more than 55 members involved;

- countless conferences;

- 02 new Board Member countries;

- 01 new strategic partnership;

- 06 open Webinars;

- + 6,300 followers at Linked In;

- 01 new strategic activity - the online course counting with 37 participants from 17 countries.

And that is not all… 550 entries to the WorldStar Packaging

Awards. An absolute record! And that leads us to 2025.

We greet the new year with the excitement of seeing the

packaging industry in high motion, exploring new technologies and drivers,

design perspectives, functionalities, accessibility and sustainable solutions.

Embarking AI and fostering automation.

The WorldStar Awards reflects the activities of the

packaging industry around the globe and there is a lot going on, focused on

more efficiency to supply chains, quality of life, safety and convenience to

consumers, material optimization and circularity for more sustainable consumption

chains.

Alongside fostering packaging innovation, in 2025 WPO will

continue to raise the voice for packaging on a global level, connecting the

global packaging industry – and I mean it with a very special new project to be

presented.

We will also continue to share knowledge and expertise on

how packaging can drive a positive impact in modern life in society, and how we

can foster to integrate packaging ready to recycle growing solutions with waste

and recycling management streams, that comes with consumers’ education and

engagement.

And last but not least, WPO will continue to expand its

capacity of building programs via local trainings and online short-term

courses.

I take this opportunity to thank each one of you reading WPO

News for your support, partnership and enthusiasm.

Let’s keep on working closely together.

A very happy and fruitful 2025. All the best!

[email protected] [email protected]

WPO – World Packaging Organization

WPO – World Packaging Organization

www.linkedin.com/in/lucianapellegrino www.linkedin.com/in/lucianapellegrino

@WorldPackOrg1

@WorldPackOrg1

worldpackagingorg

worldpackagingorg

World Packaging Organization

World Packaging Organization

Message from General Secretary

Recap of the WPO Meetings in Buenos Aires

Dear members, it is that special time of

year, when we reflect on the wonderful experiences and connections made during

the latest WPO Board Meeting. This time, we were fortunate to gather in the

beautiful city of Buenos Aires, Argentina, where the Argentinian Institute of

Packaging (IAE) extended a warm and generous welcome to the WPO.

At our meetings, we brought together around

40 participants, in hybrid format, to discuss and to plan the future of WPO.

The discussions were marked by collaboration, forward-thinking ideas, and a

shared passion for driving meaningful progress to the packaging industry. We

deeply appreciate the valuable contributions and creative solutions offered by

each and every member during these vital conversations.

Throughout the week, several pivotal

meetings took place, including the Executive Meeting, sessions for the

Education, Marketing, and Sustainability & Save Food Working Groups, as

well as the LATAM Roundtable. The highlight of our time together was the

remarkable WPO Board Meeting. In addition, we had the honour of attending IAE’s

prestigious Estrella del Sur packaging awards ceremony.

Now, as we say goodbye to this incredible

week in Buenos Aires, we want to remind you of the exciting opportunities that

lie ahead. We are delighted to announce that our next WPO Meeting will be held

alongside IPACK-IMA in Milan, Italy, from May 27-30, 2025. More details will

follow in the months ahead.

As a final administrative note, the WPO secretariat will be on leave from December 19 to

January 6, returning to activities on January 7, 2025. Until we meet again,

let's carry the spirit of collaboration and innovation in our hearts, and let's

continue to make a positive impact on the world through packaging.

Warmest regards!

Nathália Antoniazzi

WPO Secretariat

[email protected]

Johannes Bergmair

WPO General Secretary

[email protected]

From the Editor

Food waste in the climate change agenda?

By Liliam Benzi*

During the WPO week in Argentina, the event host and member of the organization, the Instituto

Argentino del Envase (IAE), organized the second edition of the IAE Conecta Forum. Opening the event,

WPO President, Luciana Pellegrino, delivered a presentation on "Global Perspectives on Packaging," highlighting trends and innovations shaping the industry.

Luciana outlined five macro perspectives that will continue to guide the packaging sector: market and innovation, niche markets, technology and digitalization, sustainability, and consumer behavior. These pillars are united by the overarching goal of achieving efficiency across all stages of the packaging lifecycle. She further stressed the importance of developing packaging solutions with a reduced carbon footprint, while emphasizing the critical role of packaging in minimizing food waste.

In this context,

Natalia E. Basso, from the Argentine consultancy Vesicabiz, addressed "Food Waste in Latin America – Challenges and Opportunities", presenting a project aimed at tackling this pressing issue.

As a result of a partnership between GS1 Argentina and IAE, the consultancy developed a platform with the goal of generating solid data to support decision-making and identifying opportunities for improvement in resource management within industries and supermarket chains through case studies on packaged food waste. Furthermore, the project aims to understand the role of packaging in preventing and reducing food loss and waste (FLW).

The project’s general goal is to assess the impact of packaged FLW using sustainability indicators —

social, environmental, and economic. Specific objectives include:

- quantifying product losses, along with their packaging;

- identifying the causes and destinations of FLW based on geographic region, store format, and seasonality;

- calculating the impact of packaged FLW using defined sustainability metrics.

Key drivers of food loss and waste

Natalia highlighted three primary causes of food loss and waste:

- Macro Causes – Systemic Factors

- Institutional, political, and contractual conditions

- Investment gaps and lack of best practices

- Meso Causes – Structural or Secondary Factors

- Infrastructure deficiencies

- Problems arising within the same supply chain stage or across different ones

- Micro Causes – Operational Factors

- Occur at each stage of the supply chain

- Actions or omissions by actors within the same phase

- Responses (or lack thereof) to external factors

It is estimated that 13.8% of all food is lost in the various stages, that goes from production to consumption, while 19% are wasted, amounting to 1.5 million tons per year. On a global scale, 30% of food is lost or wasted, making this issue a critical challenge for sustainability. One of the UN FAO’s Sustainable Development Goals (SDGs) explicitly addresses this, stating: "By 2030, halve per capita global food waste at the retail and consumer levels and reduce food losses along production and supply chains, including post-harvest losses."

These figures — and the concurrent rise in global hunger—represent a compelling call to action. Food loss and waste must urgently become part of the climate change agenda. With such alarming statistics, addressing FLW

is no longer optional; it

is imperative for fostering a sustainable future while tackling food insecurity and reducing environmental impacts.

By bridging systemic challenges, leveraging innovative packaging solutions, and fostering collaboration across the supply chain, the packaging industry can play a transformative role in combating food waste, a key driver of global carbon emissions and resource inefficiency.

*Liliam Benzi is the Editor of WPO News, WPO Press &

Communication Liaison Officer and runs its own Communication & Strategy

company for the packaging industry, LDB Comunicação Empresarial ([email protected]). She was recognized ‘Packaging Professional

of the Year’ in Brazil.

[email protected] [email protected]

(+ 55 11) 99989-1597 (+ 55 11) 99989-1597

liliambenzi liliambenzi

liliam-benzi-870b771a liliam-benzi-870b771a

Liliam Benzi Liliam Benzi

Around the World

Greece discusses security printing and

packaging interconnection in the supply chain

On October 3, WPO member in Greece, the

Association of Greek Manufacturers of Packaging and Materials (AGMPM – www.pac.gr) and Polytag organized a webinar to introduce cutting-edge tools that will revolutionize the

supply chain of packaged products in the European market

At the occasion, Polytag presented innovative and low-cost solutions that have been adopted by leading

UK landlords and retailers, such as Digital Link GS1 QR codes as well as

invisible UV labels (digital watermarks using UV inks), which are certified by

the European organization Recyclass. The tags are

used to collect data about what reaches the recycling centers, which can be

accessed by SKU producers, recycling centers and local authorities via the Polytag Dashboard. Invisible UV labels also effectively

support package sorting using optical sorting technology.

The company is a certified partner of GS1

Europe, using GS1-supported QR codes for supply chain information,

direct-to-consumer marketing and use to reward customers for recycling,

including digital deposit return systems (DRS). QR codes are expected to

replace traditional barcodes in the coming years. As an example, the webinar

mentioned the milk production and packaging company Ocado,

which piloted 22 million labels on plastic packaging and managed to communicate

with consumers and reward them for the correct disposal at recycling and collection

points of the packaging after use.

The AGMPM webinar recording is available to

members and partners. For more information, send an e-mail to Dimitris Mandis [email protected].

FSSC leads Food Safety Training for packaging

industry in Argentina

As part of the WPO week in Argentina (Nov

18-22), WPO member, Foundation FSSC (www.fssc.com)

delivered a specialized training on food safety for the packaging industry. Led

by FSSC Technical Officer, Antoinette Maake, and

supported by FSSC LatAm Representative, Juliani Arimura, the training

session marked a pivotal moment in addressing regional challenges in food loss

and waste through improved packaging practices.

The training, which inaugurated the

international week of events revolving around packaging innovation, emphasized

the critical role of packaging in food preservation, particularly in Latin

America, where 220 million tons of food are lost and wasted annually despite

millions facing food insecurity.

Antoinette’s presentation covered essential

hygiene management standards for packaging, including HACCP principles,

prerequisite programs (PRPs), and the Additional Requirements of the FSSC 22000 Version 6 certification

Scheme. Delivered in English and seamlessly translated into Spanish,

the session ensured accessibility for the 40 participants attending.

The training, co-organized by WPO, UNIDO

Latin America, Instituto Argentino del Envase (IAE – www.packaging.com.ar), and Foundation

FSSC, contributed to the advancement of capacity building to strengthen food

safety practices in the region’s packaging industry.

Significant activities in Latvia

A number of activities are being

accomplished by WPO member, the Packaging Association of Latvia (PAL - www.packaging.lv) this second semester. In

September it happened the biggest international food

and packaging industry exhibition in the Baltics ‘Riga Food 2024’, attracting 425 exhibitors from 32 countries. The Association was

there and exhibited the works submitted to the National packaging competition

‘Latvia Star 2024’.

During the exhibition, the Chairwoman of

the Board of PAL, Sandra Muizniece-Brasava,

participated in the conference ‘Design and Sustainability of Packaging’, organized

by Latvian Technology Center in cooperation with Latvia University of Life

Sciences and Technologies (LBTU). Together with PAL member Laura Berga, from Green Dot Latvia and other professionals, she took

part in the panel ‘Packaging - Design, Sensory Prism - Stereotypes,

Sustainability and Illusions’. This discussion explored the meaning and the impact

of packaging, emphasizing aspects of design, sensory perception, sustainability

and societal stereotypes.

During the discussion, experts also offered

practical solutions on how packaging can promote more sustainable and responsible

consumption. The aim of the discussion was not only to provide insight to

professionals, but also to educate consumers on how they can influence

packaging choices and use more sustainable solutions in their everyday lives.

To promote even wider use of sustainable

packaging, Packaging Association of Latvia and BT1 International Expo Company

teamed up to create a new Riga Food 2024 tradition – Riga Food 2024 Sustainable

Packaging. Industry professionals diligently evaluated packaging made by producers

and surprised three exhibitors whose packaging were recognized

as the most sustainable. This year the titles were awarded to AUGU, from Latvia,

for its packaging for artisan producers; EVADAY, from Lithuania, for their

table textile packaging; and Lviv Handmade Chocolate,

from Ukraine, for their packaging for chocolate.

Also in September, the results of extensive

one year research ‘On polymer packaging content and amount in the Latvian

market’ were presented by Sandra Muizniece-Brasava that

gave an interview on the national TV Chanell24 in the program ‘One step Ahead’. She talked about the research carried out in close

cooperation of Latvia University of Life Sciences and Technologies and Green

Dot Latvia. Over 3000 polymer packages were analyzed during the project and the

results will serve as grounding for development of more sustainable packaging

course.

The judging of the national packaging

competition Latvia Star also ended and on November 21st, the Packaging

Association of Latvia announced and awarded the winners that are eligible to

enter the 2025 WorldStar Awards. The annual

competition organized by PAL since 1996, is a multi-level competition where

submitted works evaluated by consumers and by a jury of 10 experts. Moreover, representatives

of 9-10 supporting organizations evaluate the works. After the competition,

participants receive written comments and suggestions from the expert jury for

further improvements.

ABRE renews its brand and strengthens its

role: connections that drive impact!

At the remarkable age of 57, the Brazilian

Packaging Association (ABRE – www.abre.org.br),

a WPO member, introduced its new brand in November in a special event. The refreshed

logo is a bold, purposeful brand that reflects its mission not only to renew

but to transform. At the remarkable age of 57, the Brazilian

Packaging Association (ABRE – www.abre.org.br),

a WPO member, introduced its new brand in November in a special event. The refreshed

logo is a bold, purposeful brand that reflects its mission not only to renew

but to transform.

During the event to

introduce the new visual identity, the President of the Board of ABRE, Marcos

Antonio de Barros emphasized: "More than a new brand, we are presenting a

proposal aligned with the rhythm and demands of the market. This change

responds to a clear expectation from our members: true, connected innovation

that goes beyond rhetoric to deliver real impact." During the event to

introduce the new visual identity, the President of the Board of ABRE, Marcos

Antonio de Barros emphasized: "More than a new brand, we are presenting a

proposal aligned with the rhythm and demands of the market. This change

responds to a clear expectation from our members: true, connected innovation

that goes beyond rhetoric to deliver real impact."

ABRE’s General Manager and WPO President, Luciana

Pellegrino, added: "We are all in motion—as individuals, as brands, and as

businesses. This dynamic drove ABRE to step out of its 'comfort zone' and

embrace new horizons. This renewal strengthens the trust of the entire

ecosystem co nnected to our brand. We updated our identity to amplify our core,

non-negotiable values — Transparency, Universality, and Inclusivity — guiding

us toward a future that makes sense for everyone." nnected to our brand. We updated our identity to amplify our core,

non-negotiable values — Transparency, Universality, and Inclusivity — guiding

us toward a future that makes sense for everyone."

With the new brand, ABRE embodied the

spirit of innovation as part of its DNA, positioning itself as a transformation

hub. The mission is to catalyze change in the packaging industry and to serve

as a continuous source of innovation and connections.

The rebranding also sends a clear message

to the market: ABRE is ready to embrace a new era, driving companies and professionals

to understand that innovation and creativity must start at the top and resonate

within individuals before they can ripple across organizations.

Webinar on Smart Packaging for Food Safety

and Sustainability

On 4 December 2024, Foundation FSSC (www.fssc.com) and WPO hosted a webinar

highlighting the critical role of packaging in ensuring food safety and

advancing sustainability. The session explored how innovative packaging

solutions can protect food, reduce waste, and promote environmental

responsibility.

Kelly Mulholland, FSSC Technical Manager

Quality & Safety, gave an overview of the FSSC 22000 Certification Scheme,

emphasizing its packaging requirements and their role in upholding food safety

standards worldwide. Nerida Kelton,

Vice President Sustainability & Save Food at WPO, showcased award-winning packaging

designs that balance product protection with waste reduction. Kelton also shared insights into innovative design elements

like functionality, accessibility, and shelf-life extension that address

critical challenges in the packaging supply chain.

The event also showcased the growing

collaboration between FSSC and WPO, focusing on addressing sustainability

challenges in the packaging sector. The webinar concluded with a Q&A

session, fostering further dialogue on the future of smart packaging and its impact

on the consumer goods industry. The webinar recording is available at www.fssc.com.

Webinar on paper packaging and European

regulation in Greece

On October 24, the Association of Greek

Manufacturers of Packaging and Materials (AGMPM – www.pac.gr),

a WPO member, in collaboration with the European organization CEPI

(Confederation of European Paper Industries), organized a training seminar on

the new European regulation 2023/1115. The regulation refers to the availability on the Union market and the

export from the Union of certain basic and derived products that are linked to

deforestation and forest degradation. On October 24, the Association of Greek

Manufacturers of Packaging and Materials (AGMPM – www.pac.gr),

a WPO member, in collaboration with the European organization CEPI

(Confederation of European Paper Industries), organized a training seminar on

the new European regulation 2023/1115. The regulation refers to the availability on the Union market and the

export from the Union of certain basic and derived products that are linked to

deforestation and forest degradation.

The representative of CEPI, Margherita Miceli (Forest Policy

Manager), presented the basic principles of the regulation, referred to the use

and mixing of PCR paper during the production of paper packaging. She

emphasized the importance of mass balance in paper mills, listed the exemptions

from obligations by certain SMEs (based on annual turnover and number of

employees), focused on the definitions of countries as low/medium/high risk,

and introduced the DDS registration platform. Cases of registration by

producers of paper packaging on the European platform were analyzed.

This educational webinar is available to

AGMPM members and partners. Requests by email [email protected].

From the Board

WPO week in Argentina: rich discussions, important decisons

The 112th WPO Board Meeting was held on November 21 in Buenos

Aires, in a hybrid format, with the participation of more than 30 country members. In the openning session, the President Luciana Pellegrino reinforced her belief: “Great things happen when we are together, but greater things happen when we work together”. This has also been the ‘mantra’ for her first year of mandate focused on making a real impact in the global packaging community, bringing tangible benefits for WPO members.

Two other main issues presented by Luciana were the increase in the participation of WPO members in events around the world, representing the Organization, and the raise of the voice for packaging, taking the industry to an strategic level in global conversations. Thanks to partnerships such as the one with UNIDO, in 2024 WPO accomplished 03 roundtables, with more than 30 members participating from African Arab, Asian, Latin America and Caribean regions.

Other highligths of WPO Board Meeting in Argentina:

- approval of APEE, the packaging association from Peru, as a Full Member, totaling 64 country members;

- new training courses for 2025, including the new series of online paid courses;

- continue to increase the performance of social medias and other communication tools to raise the voice for packaging;

- encourage members and its own members to use the WPO Design for Recycling Guide available for free download in 14 languages.

WPO thanks its member in Argentina, the Instituto Argentino del Envase (IAE – www.packaging.com.ar), for all the support in organizing all the activities during the week.

WPO approves Education Programs for 2025

WPO Vice President of Education, Kofi Essuman, has announced the packaging training programs approved for 2025. From 18

applications, the Education Working Group selected seven WPO members to receive the training, based on the established criteria.

The selected countries/members are:

- Indian Institute of Packaging

- Institute of Packaging and Graphic Arts Tectus (IatT), Croatia

- Moroccan Federation of Plastics Industry

- CENEM - Chile

- Venezuelan Packaging Association (CAVENVASE)

- Institute of Packaging Professionals Uganda (IPPU)

- African Packaging Organisation, Tanzania

For more information, please contact Kofi Essuman via email at [email protected].

WPO first paid online course is a success!

On Dec 03, WPO concluded its first three-hour paid online course delivered by Lina Wimmer and Charlotte Neumair, both experts from Circular Analytics.

This certificate course covered topics including:

- Overview of regulatory framework in the EU (Green Deal)

- PPWR topics, objectives and time frame

- Overview of relevant paragraphs of the PPWR

- Waste reduction

- Recyclability, Recycling at scale, Recycled content for plastics

- Packaging minimization and Reuse

- Labelling

- Obligations of packaging producers, manufacturers, distributors, retailers

The course was highly recommended to brand owners, packaging manufacturers, suppliers, retailers, freight companies; academia/professionals in the areas of Packaging, Design, Development and Production; national regulatory institutions involved in environment, production and distribution of goods; e-commerce operators, recycling companies, consumers and consumer associations.

Congratulations to WPO President, Luciana Pellegrino, and to the Vice President Education, Kofi Essuman, that put a lot of efforts to turn this course a reality.

Education

WPO first packaging training in French was a success!

WPO Education portfolio, coordinated by the

Vice President Kofi Essuman, has hit another milestone: for the first time, a

Packaging Training was facilitated in French, in Côte d’Ivoire, in partnership

with the local member, Association of the Packaging Professionals of Côte

d’Ivoire (APECI – www.apeci.ci) and with the

support of another member, the Center of Excellence in Packaging (Packtec – www.packtec.tn)

The 3-Days training program took place from Nov

28th to 30th, in Abidjan, and came as an answer to the request of WPO

local member to have a Packaging Training in French, which is the main language

of most countries in West and Central Africa.

Fourteen enrolled participants were instructed

on Packaging Fundamentals by Nouha Khaled, Packaging Trainer from PACKTEC,

supported by local facilitators Franck-Philippe N’Dia, Olivier Kamenan, and Suzanne

Mouelle (from APECI) who shared their respective expertise on Packaging as

Marketing Tool.

The packaging manufacturing learnings came

alive during a factory visit at Mici Embaci, a corrugated box and PP bags

manufacturer; all learners were granted Certificates at the end of the

training.

News from Corporate Partner

How Takeda is becoming a more sustainable company?

Recently, WPO Corporate Partner, Takeda (www.takeda.com), published in its magazine an article entitled ‘How we exceeded our goal of 50% sustainable paper packaging by 2 years’.

For this article,

WPO President, Luciana Pellegrino, was interviewed and said she recognizes the company’s bold investments, and how it pursued multiple pathways for improvement at the same time. “What stands out is the variety of technological advancements taking place simultaneously. From raw material source, to printing technology and digitalization, these efforts create a holistic approach for greater efficiency and sustainability throughout the packaging and product life cycle.”

To know more about the three innovative efforts of Takeda to make paper packaging more sustainable, you can access the complete article through the link https://www.takeda.com/our-impact/our-stories/how-we-exceeded-our-goal-of-50-percent-sustainable-paper-packaging-by-2-years/.

Worldstar

The 2025 WorldStar Awards edition will count with the President of IPPO taking part of the judging panel.

Willing to take WPO and IPPO (International Packaging Press Organisation) Cooperation MoU beyond, WPO President,

Luciana Pellegrino, and IPPO President, Lindy Hughson, met during PACKEXPO, in November, in Chicago, and agreed upon IPPO’s Presidents participation on the judging panel, contributing with their expertise. Willing to take WPO and IPPO (International Packaging Press Organisation) Cooperation MoU beyond, WPO President,

Luciana Pellegrino, and IPPO President, Lindy Hughson, met during PACKEXPO, in November, in Chicago, and agreed upon IPPO’s Presidents participation on the judging panel, contributing with their expertise.

“We understand that this partnership is valuable for both parts. Worldstar will have a truly independent packaging expert in its judging process and IPPO will be able to follow more closely the main packaging trends and innovation around the world, demonstrate in the entries”, states Luciana Pellegrino.

Commenting on the invitation, Lindy Hughson says, "It is an honour to be part of the judging panel for the WorldStar Awards, which celebrate the ingenuity and progress shaping the global packaging industry. I look forward to reviewing entries that demonstrate how innovation can drive sustainability and create meaningful value for businesses and consumers alike.

IPPO is delighted to be supporting this WPO initiative, which continues to go from strength to strength.”

Soha Atallah, Coordinator of WorldStar Award, reinforces the importance of having IPPO President as part of the jury.

“Definetely the WorldStar recognises the pinnacle of innovation and excellence in global packaging, and Lindy’s participation underscores her significant contribution to the industry and her expertise in evaluating sustainable and forward-thinking packaging solutions.”

The 2025 edition of WorldStar has a record number of 550 entries from all over the world. The winners will be announced on January 09, 2025 and the award ceremony is scheduled to May, in Milan, during IPACK-IMA 2025. For more information visit www.worldstar.org.

Region´s Report

Enhancing collaboration: Jordan, Palestine, Egypt, and

regional partners unite for Advanced Packaging Techniques Training

In a remarkable display of regional collaboration among WPO

members, the National Center for Packaging (JoPack – www.jopack.org), the Palestinian Federation of Paper and

Packaging Industries (PFPPI – www.facebook.com/pfpippal),

and other key partners successfully organized a transformative training program

titled ‘Advanced Packaging Techniques’. The program, held under the auspices of

the United Nations Development Program (UNDP), took place over four intensive

days, from September 30 to October 3, 2024.

This initiative marked a significant milestone in fostering

cooperation across the region, showcasing the shared commitment of Jordan,

Palestine, and neighboring countries to advancing the packaging industry and

enhancing the competitiveness of local businesses on a global scale.

It brought together professionals, technicians, and industry

leaders from across the region to engage in a meticulously designed curriculum

that combined theoretical knowledge with practical applications. Over the

course of the program, participants gained insight into the latest advancements

in packaging technologies, focusing on modern practices, innovative materials,

and sustainable solutions.

A distinctive feature of the program was its practical

component, which included site visits to leading Jordanian factories across

various industries. These visits provided participants with invaluable exposure

to real-world applications of advanced packaging concepts, offering a hands-on

perspective on production workflows and quality assurance practices.

In addition to observing cutting-edge packaging

technologies, participants had the opportunity to interact with key industry

leaders in Jordan. These interactions served as a platform for exchanging

knowledge and discussing challenges and opportunities within the packaging sector.

Industry experts shared valuable insights on improving production efficiency,

enhancing product quality, and adopting innovative solutions to meet global

standards.

JoPack’s broader regional training contributions

The ‘Advanced Packaging Techniques’ program builds on

JoPack’s extensive experience in organizing impactful training initiatives

across the region. JoPack has successfully implemented several key programs,

including:

■ A Diploma in Paper and Carton Manufacturing, delivered in

collaboration with Egypt, providing participants with advanced technical skills

in producing high-quality packaging materials.

■ A Diploma in Manufacturing Plant Management, also conducted

in partnership with Egypt, focusing on equipping participants with management

and operational skills for optimizing production processes in industrial

facilities.

■ A Month-long course for University graduates, designed to

bridge the gap between academia and industry by providing hands-on training in

packaging tools and techniques, preparing graduates for careers in the sector.

■ A Train-the-trainer program for Export Markets, aimed at

equipping professionals with the knowledge to guide businesses in meeting

international standards and successfully entering global markets.

Through these programs, JoPack continues to enhance the

capabilities of individuals and organizations across the region, solidifying

its role as a leader in the packaging industry.

International accreditation and market competitiveness

One of the most significant outcomes of the program was the

awarding of internationally recognized certificates to participants, accredited

by the prestigious Oxford Training College in the United Kingdom. This

certification not only underscored the credibility of the training but also

enhanced the professional standing of participants, equipping them with a

competitive edge in the global market.

By acquiring these certifications, participants are now

better positioned to contribute to the growth and modernization of the

packaging sector in Jordan, Palestine, and the wider region, leveraging their

skills to meet the evolving demands of regional and international markets.

A milestone in regional cooperation

This training program represents more than just a learning

opportunity—it is a testament to the growing collaboration between Jordan,

Palestine, and neighboring countries within the framework of the WPO. Such

initiatives underscore the potential of regional partnerships in driving

innovation, capacity-building, and economic development.

The successful execution of this program signifies a

qualitative leap in the relationship between regional partners in the packaging

sector. It reflects the shared vision of creating a strong, interconnected

industry that can thrive in the face of global challenges.

Looking ahead

As the packaging industry continues to evolve, programs like

‘Advanced Packaging Techniques’ highlight the importance of investing in

knowledge exchange and skill development to ensure sustainability and

innovation. The partnership between JoPack, PFPPI, UNDP, and other regional

collaborators sets a precedent for future collaborations, paving the way for

more initiatives aimed at fostering regional integration and building

competitive industries.

The WPO continues to play a pivotal

role in supporting such efforts, bringing together member countries to share

expertise, resources, and strategies for a more sustainable and efficient

packaging industry worldwide.

This collaboration between Jordan, Palestine, and regional

partners serves as a shining example of how regional partnerships can drive

impactful change, inspiring similar initiatives in other parts of the world.

Technical Article

Advancing laboratory accreditation: JoPack on track for ISO 17025 Certification by 2025

By Sarah Hudaib*

The National Center for Packaging (JoPack – www.jopack.org),

WPO member in Jordan, is making significant strides toward achieving ISO 17025

accreditation for its laboratories—a crucial milestone that will position the

organization as a leader in packaging testing and certification in the region.

With a comprehensive plan in place and robust efforts underway, JoPack is expected to complete the accreditation process by

the end of 2025.

Why laboratory accreditation matters

ISO 17025 is the international standard for

testing and calibration laboratories, ensuring that they operate competently

and generate reliable, valid results. For a packaging center like JoPack, this accreditation represents a step toward

delivering cutting-edge services that meet the highest global standards.

Accredited laboratories are trusted by manufacturers, regulators, and clients,

as they guarantee accurate and consistent testing procedures that underpin

product quality and compliance.

By aligning its processes with ISO 17025, JoPack aims to enhance the quality of its testing services

for Jordanian industries and build confidence among stakeholders, enabling

local products to compete in global markets.

Strategic steps toward accreditation

JoPack has implemented a structured roadmap to achieve ISO 17025

accreditation, encompassing both technical and operational improvements. Key

focus areas include:

Infrastructure Upgrades

JoPack has invested in state-of-the-art laboratory

equipment to ensure accurate and reliable testing. These upgrades align with

international standards and cover a wide range of packaging tests, including

strength, durability, and environmental impact assessments.

Staff Training and Development

A dedicated team of engineers and technicians is undergoing advanced training

to master the intricacies of ISO 17025. Through on-the-job coaching and

specialized workshops, the team is being equipped with the technical expertise

required to conduct testing procedures that meet global benchmarks.

Standardized Processes

JoPack is streamlining its operational workflows by

implementing rigorous quality management systems. These systems encompass test

method validation, data accuracy, and result reproducibility, ensuring that all

procedures comply with ISO 17025 requirements.

Collaborations and Partnerships

JoPack is actively collaborating with regional and

international organizations, including the Royal Scientific Society (RSS) and

packaging centers like PACKTEC in Tunisia. These partnerships provide JoPack with access to expert technical consultancy,

knowledge sharing, and benchmarking opportunities.

Internal Audits and Pre-Accreditation

Reviews

Regular internal audits and reviews are being conducted to assess JoPack’s readiness for accreditation. These evaluations

help identify areas for improvement and ensure compliance with ISO 17025

standards.

The Vision for 2025

By the end of 2025, JoPack envisions becoming an officially accredited laboratory, offering a

comprehensive range of testing services for packaging materials and products.

This milestone will not only benefit Jordanian industries but also position JoPack as a regional hub for packaging testing and

certification.

The accreditation will

open doors for Jordanian manufacturers to expand into international markets, as

they will be able to rely on JoPack’s certified

testing results to meet global packaging standards. Additionally, it will attract foreign investors and companies

seeking reliable and internationally recognized testing services in the Middle

East.

Driving Innovation in Packaging

JoPack’s efforts toward ISO 17025 accreditation align with its broader mission of driving innovation in the packaging sector.

By providing reliable, high-quality testing services, JoPack will play a pivotal role in fostering sustainable packaging practices,

improving product safety, and enhancing the competitiveness of Jordanian

products on the global stage.

A Call for Industry Collaboration

As JoPack approaches this critical milestone, it calls on industry stakeholders to

collaborate and support the accreditation journey. Together, the public and

private sectors can ensure that Jordan’s packaging industry becomes a model for

quality, innovation, and global integration.

Conclusion

The path to ISO 17025

accreditation is challenging but transformative. For JoPack,

this process is more than just meeting standards— it is about

building trust, advancing industry capabilities, and positioning Jordan as a

leader in packaging excellence. By 2025, JoPack’s laboratories will not only be accredited, but will also serve as a beacon of

quality and reliability for the region and beyond.

*Sarah Hudaib is

Project Manager & Testing Technician of JoPack.

For more information send an e-mail to [email protected].

Special Article

Cuba advances in the discussion about plastic

By Miriela Valle Cepero*

Cuba is joining the global effort for environmental protection through the implementation of the project ‘Development of Sectoral and Territorial Capacities to Address Plastic Pollution’. This ambitious initiative is led by the Tropical Geography Institute (IGT), part of the al Ministry of Science, Technology, and Environment (CITMA).

The oficial launch of the project took place at the IGT, where experts, academics, and entrepeneurs gathered to discuss strategies and share experiences.

In this opening remarks, Alfredo Luis Gil Rodríguez, the project leader, emphasized the importance of collaboration among different sectors to face this challenge. The oficial launch of the project took place at the IGT, where experts, academics, and entrepeneurs gathered to discuss strategies and share experiences.

In this opening remarks, Alfredo Luis Gil Rodríguez, the project leader, emphasized the importance of collaboration among different sectors to face this challenge.

The first presentation was made by Belsis Llorente Díaz that presented relevant national policies and regulations, highlighting the National Environmental Strategy 2021 – 2025, and the Circular Economy Transition Strategy 2022 – 2026, which seeks sustainable development in the country.

The current status and the future projections of the National Center for Packaging and Packing (CNEE), WPO

local member, were discussed by the specialists Miriela Valle Cepero and Niurka García Roque that explained that the CNEE’s objective is to lead and to implement the approved policy for the development of the packaging and packing industry in Cuba.

As part of this implementation, keys indicators are evaluated, along with the participation of produced and imported plastics and their environmental impact.

The workshop served as a platform for exchanging ideas and to foster enriching dialogue among participants. This project is a call to action that invites collaboration among various social actors in Cuba. With this proactive approach, Cuba demostrates that it is possible to move towards a healtier future, based on a collective commitment to environmental preservation and a call to action for all.

*Miriela Valle Cepero is from CNEE, WPO member in

Cuba. For more information, send an e-mail to [email protected] or [email protected].

Special Article

Luxury packaging: technical characteristics

and market segmentation

By Alessandra Alessi*

Luxury goods packaging is designed to reflect

the exclusivity and value of the product, as well as to offer a memorable

experience for the customer. The main features of luxury goods packaging

include:

- High-quality materials: Premium and durable

materials such as wood, metal, glass, leather, or high-end cardboard are used,

often with glossy or matte finishes. These materials must not only protect the

product but also enhance its image of exclusivity.

- Sophisticated design: The packaging design is

often minimalist but extremely detailed, with clean lines and elegant shapes.

Aesthetics are essential to convey a sense of luxury.

- Customization: Luxury packaging is often

highly personalized, with bespoke elements such as engravings, monograms, or

unique prints that reflect the brand’s identity or the customer’s preferences.

- Advanced printing technologies: High-quality

printing techniques such as embossing, hot stamping, metallic foil, embossing,

or screen printing are used. These techniques give the packaging a luxurious

and distinctive appearance.

- Colors and finishes: The colors tend to be

sober and refined, such as black, gold, pearl white, or other elegant shades.

The finishes can be matte, glossy, or satin, often with metallic or iridescent

details.

- Attention to detail: Every element of the

packaging is meticulously crafted, from the inner lining, often in silk or

velvet, to magnetic closures or silk ribbons, to offer a complete sensory

experience.

- Innovation: Luxury packaging often integrates

innovative solutions, such as hidden magnetic closures, LED lighting, or

elements that engage the customer on a tactile or sensory level.

- Eco-sustainability: There is a growing focus

on sustainability in luxury packaging, with the use of recycled or eco-friendly

materials without compromising appearance and quality.

- Unboxing experience: The moment of opening the

packaging is designed to be an emotional experience, with attention to how the

product is revealed to the customer. This includes the use of multiple layers

or a dramatic presentation of the product.

- Discreet but recognizable branding: The logo

and brand elements are present but not dominant, in line with a sophisticated

aesthetic. Tone-on-tone colors or textures are often used to keep the branding

subtle but recognizable.

These combined elements help create packaging

that not only protects the product but also communicates the brand’s values and

the luxury experience it aims to offer.

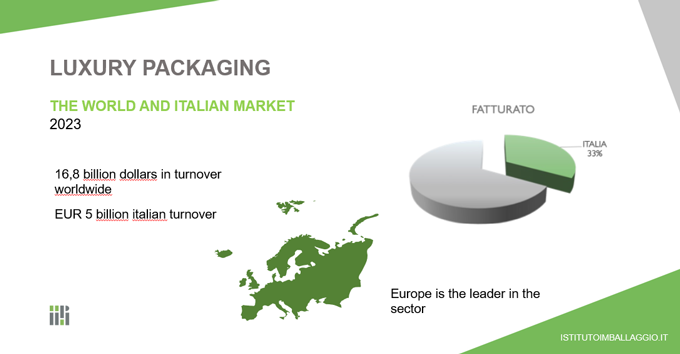

Italy, together with France, ranks among the

world’s leading players in the production of packaging for luxury goods. In fact,

many European countries, such as Italy, France and Germany, have a long

tradition of high-quality craftsmanship and design and are known for their

ability to create exclusive and elegant packaging, using fine materials and

sophisticated workmanship.

In addition, the presence of numerous fashion

and luxury houses of world-renowned, the growing attention to environmental

sustainability and regulations on packaging among the most stringent in the

world, drive innovation and competitiveness in the sector.

From a worldwide overview, from the USA come

solutions and technologies - like augmented reality and "smart"

materials - which meet the need of US companies to have high quality packaging

that exploits attractive designs and the moment of unboxing to create memorable

shopping experiences, necessary to emerge from one of the world’s largest

markets.

Asia has significant influence on the high-end

packaging market. While the Middle East is characterized by a culture that

places great emphasis on aesthetics, personalization and customer experience,

China (which has become a leading luxury market globally) is also noted for the

use of traditional materials such as paper, silk and wood, processed with

innovative techniques and combined with modern materials or interactive

technologies to create exclusive packaging.

*Alessandra Alessi is responsible for Communication

at Istituto Italiano Imballaggio (www.istitutoimballaggio.org),

WPO member in Italy. For more information send an e-mail to [email protected].

|